Black Gold Under Pressure

September 5, 2025

Millions of barrels of crude oil are produced worldwide every day. Vapor pressure measurement plays a crucial role in the safe transport, storage, and processing of crude oil and fuels. An explosion-protected enclosure solution from Pepperl+Fuchs enables precise 24/7 measurements directly in the process.

Between Oil Sands and Desert Sands

Canada, icy minus 40 °C degrees in winter. In contrast, 50 °C degrees in the Saudi Arabian desert in summer. Two countries whose climatic contrasts could hardly be more drastic, yet they have one thing in common. Both are among the largest oil producers in the world and ensure that millions of barrels of crude oil are available every day as fuel, for power generation, or in the chemical industry for the production of plastics, cleaning agents, or paints. While viscous oil is extracted from oil sands in the Alberta region in western Canada, an almost diesel-like crude oil comes to light in Saudi Arabia’s desert. The fossil raw material, which has been formed over millions of years through the decomposition of organic substances in the earth’s crust, passes through numerous processes and stages: complex extraction, processing in refineries, transportation over long distances, and storage and interim storage in tanks and terminals. One central guiding principle applies to all these stages: the quality of the “black gold” must be monitored precisely at all times. It is not only the economic value that depends on this, but also the safety of plants, people, and the environment, as crude oil and oil mixtures are known to be explosive substances.

An invisible variable plays a central role here: vapor pressure. It indicates how easily a liquid evaporates and is an important parameter for the safe storage, processing, and transportation of crude oil and petroleum products. It varies greatly depending on the composition of the raw material and the temperature. Excessive vapor pressure can lead to increased flammability and explosion, especially in closed systems such as pipelines, terminals, refineries, and tank farms. This is exactly where the “eravap online” vapor pressure measuring device from eralytics, based in Vienna, Austria, comes into play. Developed for continuous operation under the harshest conditions in explosion-hazardous areas, it delivers laboratory-quality measurement results worldwide, thanks in large part to an explosion-protected enclosure solution from Pepperl+Fuchs.

Process Measurement in Laboratory Quality

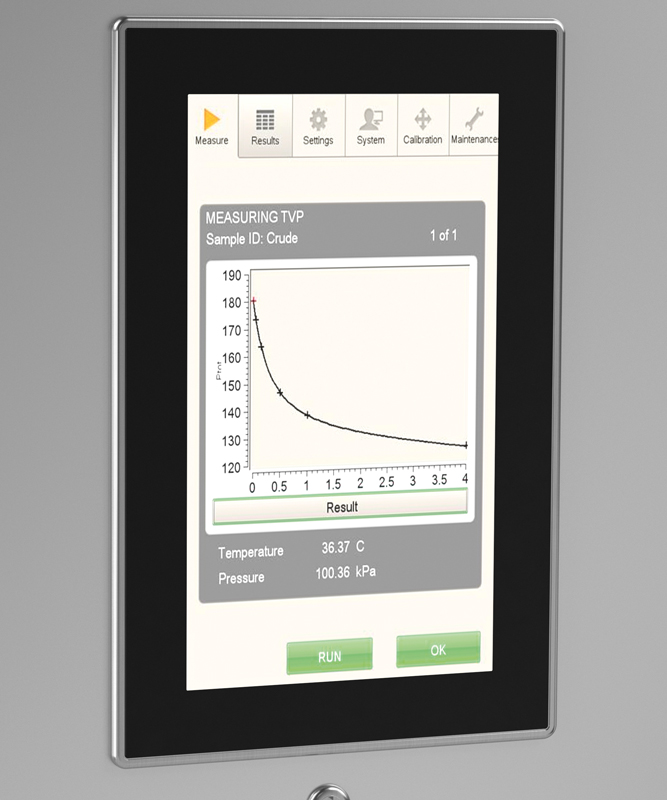

Eralytics has been developing and producing a wide range of analytical devices for the quality control of liquids since 2007. With eravap, the company launched the first fully automatic laboratory measuring device for measuring the vapor pressure of gasoline and crude oil, which featured a color touch screen and a modern industrial PC with USB and Ethernet interfaces. The absolute accuracy, functionality, and user-friendliness of the device were convincing. “As a result, we were successful very quickly and were able to achieve a larger market share in a short space of time,” recalls Philipp Jordan, company owner and founding member of eralytics. But that’s not all—what used to be done exclusively in the laboratory is now possible directly in the process: “We were repeatedly asked by our customers whether we could also offer our vapor pressure measuring device as a process device,” says Philipp Jordan. The engineers at eralytics therefore developed the eravap online process measuring device from the successful eravap laboratory instrument, which is designed to measure around the clock in the running process. The measured values are transmitted digitally and in real time from the field to the control room via the Modbus communication protocol.

The customized explosion-protected enclosure solution from Pepperl+Fuchs enables continuous vapor pressure measurement of crude oil and gasoline directly in the process.

Precise, Safe, and Digital

“With eravap online, we are the only provider that can comply 100 % with laboratory standards when measuring the vapor pressure of crude oil and gasoline. This absolute accuracy makes process monitoring and quality control much easier for refineries, tank farm and pipeline operators, as time-consuming comparative measurements with laboratory equipment are no longer necessary. In addition, if the end product changes, the process measurements do not have to be recalibrated again and again, as is usually the case with competitor devices,” explains Philipp Jordan. “This is how we, as a rather small Austrian company, were able to gain a foothold in the oil industry in the first place,” reports the company owner proudly.

However, in order to be allowed to measure in the process at all, a solution for use in explosion-hazardous areas had to be found first. The basis for this was a tailor-made explosion-protected enclosure solution with an integrated 15-inch touch screen monitor from the VisuNet FLX Series and the 6000 Series purge and pressurization system from Pepperl+Fuchs.

“For the analysis of combustible liquids, only the Ex p (pressurization) type of protection was an option. This makes it possible to operate non-explosion-protected electrical devices inside a pressurized enclosure in explosion-hazardous areas,” explains Werner Lebitsch, Head of Process Automation at Pepperl+Fuchs in Austria. The enclosure to be protected is first flushed with an inert gas such as nitrogen and then a slight overpressure is generated inside, which prevents the ingress of a potentially explosive atmosphere. However, this is often a challenge for terminals without their own nitrogen supply. “This is where the solution from Pepperl+Fuchs was convincing compared to comparable devices: The amount of nitrogen required is particularly low with the 6000 Series purge and pressurization system. This is a decisive criterion for our customers,” emphasizes Philipp Jordan.

The entire pressurized enclosure solution, including the touch screen monitor, is triple certified to UL for Class I, Division 1 and to ATEX and IECEx for Zone 1, and can therefore be used worldwide.

Extremely Easy Servicing and Operation

The measuring instruments run around the clock under the toughest conditions. The software communicates via modern communication protocols and the mechanics are designed for quick and easy servicing. “When it came to servicing, it was particularly important to us that the measuring cell could be replaced quickly. The solution from Pepperl+Fuchs allows the replacement to be carried out within a few minutes, without long downtimes or time-consuming staff training,” praises Philipp Jordan. After replacement, the housing is simply closed again, flushed with nitrogen and pressurized. The system is then ready for use.

The integrated touch screen monitor of the VisuNet FLX series not only enables intuitive operation, but is also explosion-protected. The 15-inch display offers a convenient user interface, specifically when calibrating or resetting parameters, without having to open the enclosure. With up to three parallel sample streams and a quality control stream as well as digital data transmission in real time to the control room, eravap online has now become an indispensable measuring instrument for refineries, mixing plants, and terminals.

Flexible Solutions Require Flexible Partners

This success is also thanks to the well-established collaboration with Pepperl+Fuchs, which began back in 2018: “We had previously purchased a solution from another provider. But together with Pepperl+Fuchs, we developed a new, much more flexible solution that could be continuously adapted to new requirements over the years—from the software to the hardware to the design,” reports Philipp Jordan. “We always had direct contact, short paths, quick reactions. That is worth its weight in gold when our customers need a quick solution,” says Philipp Jordan, praising the support from Pepperl+Fuchs, especially from the Group’s own Solution Engineering Center in Bühl, Germany, which develops, manufactures, and lets certified the customized solutions for explosion protection.

Successful Together

“The solutions business is highly exciting for us at Pepperl+Fuchs because we work closely with our customers to develop customized and tailor-made solutions. This gives us the opportunity to constantly learn about new applications and innovative processes, which makes our work varied and inspiring,” says Werner Lebitsch, adding: “We attach great importance to working in partnership as equals, as this is the only way we can create the best and most sustainable solutions together.” Today, more than 80 eralytics vapor pressure gauges with the pressurized enclosure solution from Pepperl+Fuchs are already in use worldwide: the majority of them in the USA and Canada, followed by Saudi Arabia. But Austria’s largest mineral oil and chemical company also relies on eravap online for vapor pressure measurement. Although the climatic conditions in the Alpine republic may not be quite as challenging as in Canada or Saudi Arabia, precise vapor pressure measurements and reliable explosion protection are in demand wherever black gold is extracted, transported, or processed.

Learn more

Our Solutions,

as Individual as You

Vapor Pressure: The Invisible Variable

In refineries, vapor pressure is a decisive parameter for product quality, process optimization, safety, and compliance with environmental protection criteria. Crude oil consists of a composition of different hydrocarbons. In the refinery, the individual components are separated from each other in order to obtain different petroleum products. “Blending” involves mixing different components to produce fuels such as petrol with different octane ratings, diesel, or kerosene. Accuracy is especially important here: If the vapor pressure is too low, the gasoline mixture in the engine will not ignite later; if it is too high, the fuel evaporates during refueling and is released into the environment. The limit values for the vapor pressure of liquid petroleum products are therefore subject to strict legal regulations. By precisely measuring the vapor pressure, the addition of butane can be carefully dosed to increase the vapor pressure of gasoline in accordance with legal regulations. For the refinery, this means considerable cost savings and ensures consistent product quality with optimum processes.

However, vapor pressure already plays a decisive role during transport from the extraction point. Crude oil extracted from oil sands is so viscous that it can only be transported with the help of additives. This mixture must be closely monitored before it reaches the pipelines, as excessive vapor pressure can lead to an explosion.

The demands on the measuring instruments for vapor pressure testing are high: on the one hand, they have to withstand extreme cold, such as in Canada and Alaska, and on the other, temperatures of over 50°C in Saudi Arabia. Added to this are sandstorms, snow and ice, vibrations, and constant pressure.

Subscribe now

Would you like to find out more about customized solutions from Pepperl+Fuchs? Register via the form below to receive regular updates.

Receive regular updates on customized solutions from Pepperl+Fuchs!

Subscribe now