Individuality According to Standard: Customized Solutions for Explosion Protection

August 6, 2025

Technical expertise, many years of experience, and regional proximity: This is the basis on which Pepperl+Fuchs’ global Solution Engineering Centers (SECs) develop reliable system solutions for electrical explosion protection.

With a high-precision movement, the piston rods of two hydraulic cylinders extend centimeter by centimeter in synchronization with each other. In perfect unison, the swivel frame connected to them slowly tilts degree by degree before a steady stream of highly heated aluminum finally pours out of a funnel into a rectangular housing mold. This process appears almost leisurely, which makes it seem like a contrast to the otherwise bustling environment at the Pepperl+Fuchs Solution Engineering Center (SEC) in Chennai, India.

Gravity tilt casting helps minimizing air inclusions.

In this case, however, the perceived slowness is an important means to an end: "The gravity tilt casting process minimizes air inclusions and achieves an extremely high material density. This enables us to produce cast metal housings of the highest quality and resilience. These form an ideal basis for our customized solutions for explosion-hazardous areas and also exemplify our exceptional vertical range of manufacture," explains Muthu Siva, Head of SEC in the Chennai metropolis on the Bay of Bengal. But it is not only in Chennai that quality and vertical integration are top priorities: in Houston, Melbourne, Shanghai, Burago in Italy, and Bühl in Germany, everything at the Pepperl+Fuchs SECs there also revolves around one theme: highly reliable, customized solutions for electrical explosion protection.

More than Intrinsic Safety

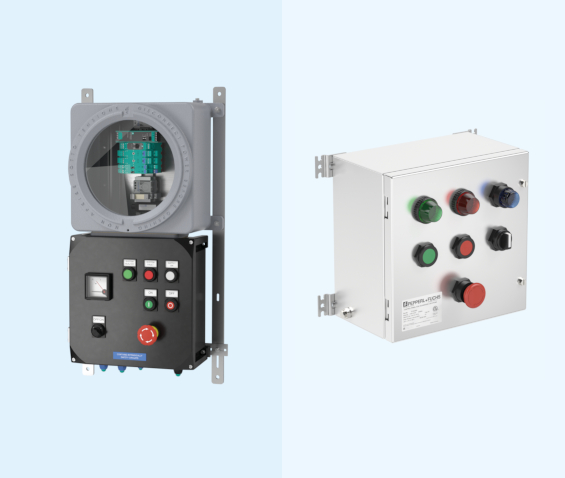

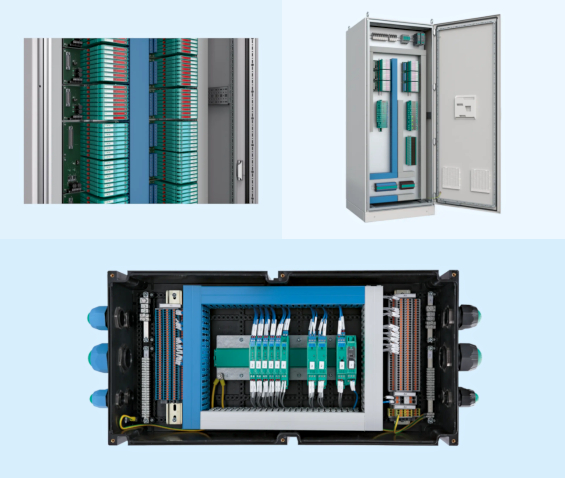

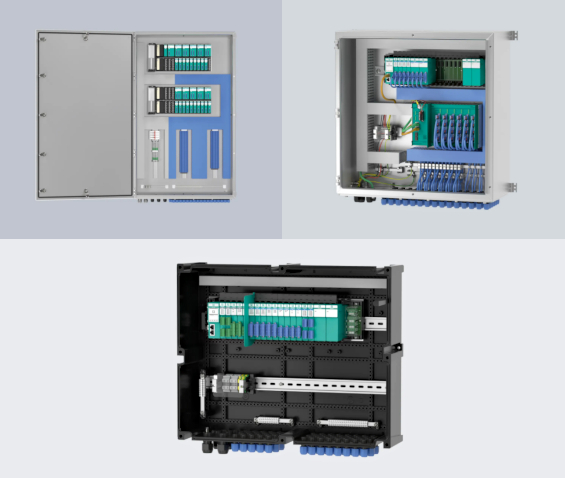

This global SEC network did not come into being overnight, but is the result of a long tradition: "Pepperl+Fuchs has played a decisive role in shaping electrical explosion protection since the 1960s and is known worldwide for its intrinsic safety components such as interface modules. Over the course of this time, we have continuously expanded our expertise. Today, we offer our customers fully certified complete solutions for measuring, controlling, regulating, switching loads, and distributing energy in explosion-hazardous areas—with Ex e, Ex d, Ex i, and Ex p types of protection," explains Jürgen Bächtle, Head of the Process Solutions business unit at Pepperl+Fuchs.

One-Stop Shop in Regional Proximity

This approach addresses the trend that many customers want to focus on their actual core business and are happy to place such a responsible and demanding task as electrical explosion protection in the hands of an experienced partner. This applies to large industrial companies as well as automation companies, engineering and planning offices, and system suppliers for large plants. Regional proximity to these customers and a deep understanding of the relevant explosion protection regulations are basic prerequisites for successfully meeting the often complex and highly individual requirements.

The choice of locations was based on the shortest possible distance to industrial hot spots or good infrastructural connections, as in the case of SEC Bühl, which is located in the Black Forest in Germany. "We are located close to the border triangle between Germany, France, and Switzerland and supply customers throughout Europe with customized solutions for electrical explosion protection," reports Kevin Korsten, Site Manager of SEC Bühl. In addition to regional proximity, another decisive advantage often tips the scales in favor of Pepperl+Fuchs in the highly competitive global project business: "We differ from other enclosure manufacturers in that we are both an enclosure manufacturer and a market-leading component manufacturer that produces, for example, isolated barriers, signal conditioners, remote I/O modules, purge and pressurization systems, fieldbus components, and HMI terminals in-house. This allows us to plan highly integrated solutions and access the company's own stocks during assembly. This saves the customer significant time by eliminating the need for coordination and purchasing," explains Korsten.

Individuality Through Standardization

The sophisticated SEC concept also includes largely standardized processes, for which Pepperl+Fuchs has even created a dedicated department. "We don’t just sell products. We deliver purpose-built solutions that are engineered around our customers’ exact needs. This diversity is best managed with a clearly defined work process for all SECs. This is the only way to implement complex projects quickly and reliably," outlines Siva. This process begins with an in-depth initial consultation and application analysis before components are selected and the solution goes into detailed engineering. "It is important to us that the customer has a fixed contact person and is involved in the progress of the project at all times. We cover this via the Order Management Units, OMUs for short, in our SECs. We model the solution virtually and first create production and approval drawings before we procure material and the solution is then manufactured," says Siva. Even after production and assembly, the customer's needs are the top priority. For example, individual test procedures and the use of specific testing software are possible. "We have also set up our own FAT areas in our SECs, where the respective customer and their contact person have the opportunity to inspect the finished solution together on site," adds Korsten.

Focus on Certification

One issue that particularly concerns customers is certification for explosion-hazardous areas: "Electrical explosion protection combines technical, safety-related, and legal requirements and entails an enormously high documentation obligation. Pepperl+Fuchs covers all of these aspects for its customers. They experience a noticeable relief because they receive a fully certified solution from us that they can put into operation in explosion-hazardous areas with a clear conscience. Other enclosure manufacturers simply cannot provide this in this depth due to a lack of approvals or specialist knowledge," explains Bächtle. This is where the concept of regionally based SECs once again proves to be a major success factor: "Each SEC is deeply rooted locally and is particularly familiar with the relevant norms, standards, and application requirements in its respective region."

Specialized Expertise on Site

This can also be observed during a visit to the Pepperl+Fuchs SEC in Australia's second largest city, Melbourne: Inside its expansive facility, a five-ton single girder overhead travelling crane, powered by a high-performance motor, spans the entire workshop. This is not just a logistical convenience—it is a critical enabler of the SEC’s operations. “We work with customers whose systems are deployed in offshore oil and gas platforms, maritime environments, and coastal processing plants,” says SEC Manager Paul Bruno. “These are not lightweight systems. The control panel assemblies we design are built onto robust, often custom-fabricated frameworks. Without this crane, moving and safely packing these heavy-duty solutions would be impossible. It’s fundamental to how we safely and efficiently operate,” he further explains the necessity of the mechanical helper.

Control panel assemblies are often built onto very robust frameworks

The need for such robust infrastructure becomes evident when considering the extreme conditions these systems face. Salt-laden air, seawater, harsh UV radiation, aggressive chemicals, and airborne contaminants subject every component to ongoing environmental stress. To ensure each solution performs reliably under these conditions, the SEC in Melbourne houses a specific space for painting. “Our dedicated paint booth provides a controlled environment, which in turn gives us the technical capabilities to apply a wide range of coatings and finishes tailored to customer specifications,” Bruno says. “Detailed paint thickness measurements are taken to verify compliance with both ignition protection and corrosion resistance standards.” Once coated and cured, each solution is finished with a laser-engraved Ex marking—built for longevity and resilience even in the harshest environments. “Here too, we offer flexibility—customers can choose the label material, format, and placement,” Bruno adds, highlighting the SEC’s commitment to customization and quality assurance.

The SEC Melbourne also has its own paint booth, where customer-specific wishes can be implemented.

The SEC Melbourne also has its own paint booth, where customer-specific wishes can be implemented.

Continuous Optimization

Although there are location-related differences between the individual SECs, they are united by their striving for ongoing optimization in the interests of the customer. For example, they have switched from the parallel production of several solutions to the one-piece flow method, which shortens throughput times. In addition, a portfolio of certain standardized Ex solutions has been defined, which are available from stock: "Our two latest enclosure series, GR and SR, are highly modular and are used as the basis for the majority of our Ex e solutions. With the standard variants from these series, we can cover numerous customer requirements particularly quickly and efficiently," says Bächtle, outlining the reasoning behind this approach. "We have also developed configurators for customer-specific variants from this standard portfolio. This allows us to combine flexibility in design with short delivery times. Our customers appreciate this more than ever," he adds.

When it comes to the final shipping of solutions, SECs use another creative trick to supply customers as quickly as possible: "Shipping large and heavy control cabinets or racks is difficult to integrate into Pepperl+Fuchs' centralized logistics. This is why the SECs manage their own delivery logistics. This not only allows us to ship quickly, but also to implement special requests for the packaging of the solution," says Bächtle, expressing his satisfaction with the results.

In addition, the SECs are utilizing the potential of digitalization and are once again using components from Pepperl+Fuchs—in this case, however, as end users: where previously printed documents were handed over, employees now use robust industrial tablets from the company's own portfolio to exchange design data between engineering and the production line. They are also proving to be a helpful aid in quality assurance: inspection checklists can be processed quickly and precisely, and once completed, forms can be stored securely.

Robust industrial tablets from Pepperl+Fuchs' own portfolio are used to exchange design data between engineering and the production line.

Robust industrial tablets from Pepperl+Fuchs' own portfolio are used to exchange design data between engineering and the production line.

A Changing Solutions Business

However, the influence of digitalization on the SECs is not only evident in internal processes, a change is also noticeable in incoming customer inquiries, as Bächtle explains: "Today, it's no longer just about simple switching and control tasks. New and much more networked communication infrastructures are currently emerging in the process industries as part of digitalization." Pepperl+Fuchs is making an important contribution to this: "We have been driving the development of Ethernet-APL from the very beginning and introduced the first Ethernet-APL Rail Field Switch to the market. Now we are helping users to securely connect the Ethernet backbone of the systems with the instrumentation in the field. To this end, we manufacture large quantities of suitable field junction box solutions in the SECs. We are also seeing a high demand for individual HMI solutions due to increasingly digitalized production environments."

Wireless communication is another topic that is becoming increasingly relevant in process plants. Pepperl+Fuchs also offers the right solutions for this: Conventional industrial wireless access points are mounted in special enclosures with type of protection Ex nR, which make it possible to use them in explosion-hazardous areas up to Zone 2/22. "Whether classic tasks, requirements from the area of operation and monitoring, or Ethernet-based infrastructure for IoT in hazardous areas: With the SECs, we at Pepperl+Fuchs have created a global structure designed to go beyond individual customer requirements," summarizes Bächtle.

Subscribe now

Would you like to find out more about customized solutions from Pepperl+Fuchs? Register via the form below to receive regular updates.

Receive regular updates on customized solutions from Pepperl+Fuchs!

Subscribe now