May 28, 2019

Tunnel Vision

Kilometer-long supply lines, waste disposal lines, and countless transport routes form an extensive network of tunnels underground. Here, in complete darkness and harsh ambient conditions, the R2000 laser scanner from Pepperl+Fuchs helps ensure that the underground infrastructure remains intact.

Block after block of high-rises, huge skyscrapers, a dense transportation network, and hustle and bustle in the streets—this is a fairly typical description of a big city. But what really keeps a city going doesn´t just happen above ground. Whether used for sewage, water, gas, or district heating, extensive tunnel networks are a key component of urban infrastructure. The work below ground is essential to things running smoothly on the surface. This means it is all the more important to ensure regular checks and maintenance so structural defects such as cracks and leaks can be detected and prevented early on. The job is tough because the conditions underground are extreme: temperatures are low and humidity is high. It is also dirty, cramped, and completely dark. In places that are too difficult, dangerous, or simply inaccessible for humans, mobile robots are becoming increasingly popular for measurement, inspection, and maintenance tasks.

'Our goal is to develop a solution that can be used to increase the intelligence, autonomy, and efficiency of these robots,” explains Jameel Marafie, co-founder and CEO of Headlight AI. Based on powerful sensor technology from Pepperl+Fuchs, the London-based start-up has developed an intelligent multisensor system that allows mobile robots to react to and create a precise, 3-D depiction of their surroundings.

Creating a Virtual Tour through Data Acquisition

A four-wheel, remote-controlled robotic pathfinder makes its way through the darkness with the help of a live sensor feed. It is equipped with various sensors that enable it to see and feel the unknown terrain that surrounds it. 'Extra rugged and accurate sensor technology is required to create a realistic 3-D image of the tunnel, because even a few millimeters of slight damage to the tunnel wall must be reliably detected under the most demanding ambient conditions,' says Marafie, explaining the requirements for the sensor. 'Our R2000 2-D LiDAR sensor possesses all of the features necessary for this application,' confirms Arno Hagemann, Business Development Manager at Pepperl+Fuchs.

The R2000 2-D LiDAR sensor ensures reliable and clear measurement results with Pulse Ranging Technology.

The rugged photoelectric sensor provides reliable and highly precise measurement results with 360° all-round visibility. It is equipped with innovative Pulse Ranging Technology (PRT) to carry out this function. "This measurement method involves a powerful light source emitting short, high-energy pulses, which are reflected by the target object—in this case, the tunnel wall—and then captured again by a light-sensitive receiver element," says Hagemann, clarifying the operating principle. "The distance to the target object and information about its surface can then be determined by the time it takes for the light to travel from the emitter to the receiver and the reflected energy." With 252,000 individual measurements taken per second and an angular resolution of 0.014°, the mobile robot is able to scan the tunnel quickly, precisely, and touch-free.

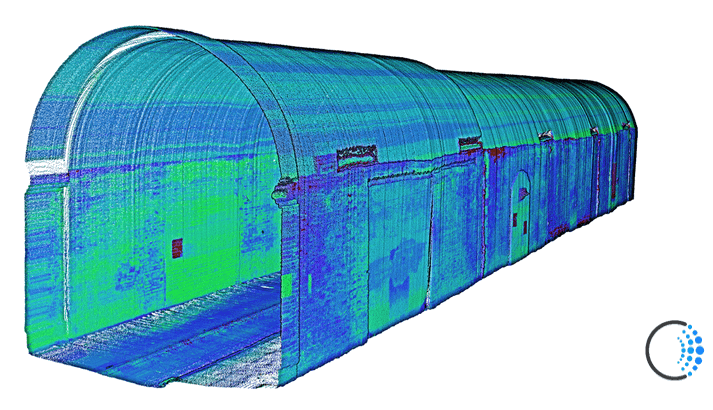

Nothing escapes the system: Even the smallest of cracks, contaminants, and other structural anomalies on the surface of the tunnel wall can be detected with millimeter precision. At the same time, the software from Headlight AI combines the measurement data obtained from millions of individual scan points to create a single compact point cloud. "We are able to create a precise image of the entire tunnel in near real time with a single measurement" says Marafie. He adds: "This means a virtual tour of the tunnel is possible at any time and provides information about its condition."

Using the measurement data provided by the R2000 laser scanner, a precise 3-D image of the entire tunnel is created in real time.

Two Birds with One Stone

Unlike delicate camera-based procedures, laser scanners work effectively regardless of lighting. The darkness in tunnels does not affect functionality in any way because the sensor itself uses a laser beam to illuminate the object and carry out an active measurement process. 'This completely eliminates additional lighting costs,' says Marafie. “Current systems are also much more expensive.' When combined with the integrated, high-precision sensor technology, the new multisensor system not only takes much more precise measurements than camera-based systems but is also significantly cheaper.

New Ground Is Already in Sight

As part of the new multi-sensor system from Headlight AI, the R2000 laser scanner from Pepperl+Fuchs has already been used in tunnel inspection and maintenance with great success on multiple occasions. Underground is just one of many areas where this technology can be used. For example, Headlight AI is developing a self-learning system for use in applications where visibility is especially poor due to mist, dust, smoke, and rain. 'We have our sights set on search and rescue drones and autonomous transport for all weather conditions,' says the ambitious start-up co-founder of future projects. Marafie goes on to add: 'Rugged and powerful sensor technology also forms the basis for this work. With the expertise and experience that Pepperl+Fuchs has to offer, we feel like we have the perfect partner by our side.'