September 8, 2020

1, 2, 3, 4, … 5G – The (R)Evolution of Mobile Wireless Standards

Three industry experts explain what makes 5G technology so attractive for companies in the field of automation technology and with what visions they are approaching the topic.

Recently, no other technology topic has received as much media attention as the ongoing introduction of 5G networks. Private users have high expectations for the new wireless network standard—but the expectations of industry stakeholders are even higher. Dr. Christian Bauer, Lead Developer 5G at machine builder TRUMPF, Dr. Werner Thoren, Technology Manager at Endress+Hauser, a global supplier for process automation, and Benedikt Rauscher, Head of Global IoT Projects at sensor specialist Pepperl+Fuchs, explain what makes 5G technology so attractive for automation technology companies and what plans they have for it.

Benedikt RauscherI think there are a variety of reasons. We live in the age of digitalization and the Internet of Things. Topics linked to this megatrend automatically become top stories in the media. Businesses and private users are always interested in innovations and developments.

Dr. Werner ThorenSmartphones and mobile devices are now the main channel for accessing offers, information, and services at any time and from any location. Take navigation as an example—who still uses an atlas or a city map (laughs)? The need to maintain social connections over any distance is another key driver. 5G promises enhanced performance and availability for this purpose.

Dr. Christian BauerIn Germany in particular, there was widespread media coverage of the spectrum auction involving telecommunications companies and the prices achieved. Anyone who reads in the news that a fierce bidding war worth billions of euros is taking place will inevitably develop an interest and consider what the implications are for them as an end user and why such large sums are at stake.

Dr. Werner ThorenThe most common demand is for higher data rates. 5G can achieve download speeds of up to 20 Gbit/s. This level of performance unlocks new potential for media streaming and virtual augmented reality, even via hotspots used by many people at the same time.

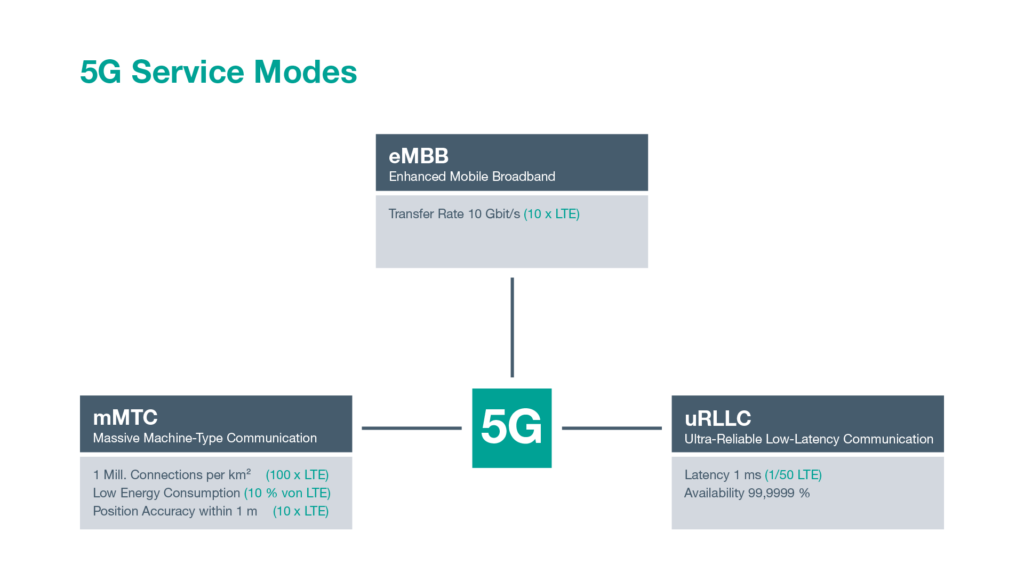

Dr. Christian Bauer5G is divided into three service modes, which are useful for explaining the advantages of the new technology. The extremely high data transfer rates we mentioned earlier are referred to as 'eMBB'—short for 'enhanced Mobile Broadband.' The benefits of the other two service modes, uRLLC and mMTC, may not be as tangible for the end user as those of eMBB, but they will still have an indirect impact on daily life.

Benedikt Rauscher'uRLLC' stands for 'Ultra-Reliable Low Latency Communication.' This describes the high availability of 5G, which is especially relevant for safety-critical applications in the process industry. 'mMTC' stands for 'massive Machine Type Communication,' i.e., the complex communication between machines and their components via an enormous number of connections in a confined space, such as the structure of a highly automated factory. Private users are more likely to encounter these two service modes via industrial products rather than via the 5G mobile wireless standard.

Dr. Werner ThorenLooking at the development of mobile wireless standards since the start of the 1980s, it is clear that we are now seeing the next evolutionary step in an increasingly digitalized world: 1G networks were used exclusively for analog voice transmission; 2G was also able to transmit SMS and MMS. 3G added video and mobile internet, while 4G added real-time audio and HDTV. 5G offers enhancements that will drive digitalization in industry.

Dr. Christian BauerThe standards we have talked about helped to network people. In contrast, 5G will be the first standard to network machines on a large scale—on behalf of people. M2M or 'machine to machine communication' is the key concept here. The introduction of 5G can also be regarded as a revolutionary step in the evolution of wireless networks in industrial environments. In this specific context, 5G is more of a communication standard than a mobile wireless standard.

Benedikt RauscherEstablished mobile wireless standards are only a medium-term solution for industrial applications. For example, GSM is widely used but consumes more energy to establish the connection than to transmit the data. This issue is especially challenging for the power supply of a battery-operated sensor. At Pepperl+Fuchs, 5G will give us much more freedom to develop wireless sensor solutions that transmit data via the mobile wireless network with low cycle times.

Benedikt RauscherIt's no coincidence that 5G has developed as a solution for industry—it's the result of a combined effort by several stakeholders. 5G is like no previous mobile wireless standard since it has been shaped by the requirements of operation technology (OT) companies, including TRUMPF, Endress+Hauser, and Pepperl+Fuchs.

Dr. Christian BauerIn the past, MSR technology had to be adapted to specific characteristics of a mobile wireless standard, or components simply had to be wired. This was the only way to achieve consistent communication. 5G changes this relationship. Both ends of the communication chain have worked together closely since development began, i.e., the OT manufacturers have worked with stakeholders in the ICT industry, including chip manufacturers and network providers such as Intel, Qualcomm, Telekom, and Vodafone. Harmonization is essential for the standard to benefit all users.

Dr. Werner Thoren5G's success is not certain. After all, industrial networks are much more demanding in terms of reliability and availability. It will be essential for OT and ICR representatives to continue working together to find common solutions. The 5G Alliance for Connected Industries and Automation forum (5G-ACIA for short) hosts most of this dialog. The forum was set up as an extension of a 5G task force founded in 2017 by the German Electrical and Electronic Manufacturers' Association (ZVEI). It brings together key players from both industries, plus representatives from academia and other associations. 5G-ACIA aims to complement existing standardization committees and associations, such as 3GPP and the NGMN Alliance, and therefore champions the need for an industry-oriented 5G standard.

Benedikt RauscherThis topic is interesting for Pepperl+Fuchs from several perspectives. First, we see ourselves as an innovative and curious company—that's part of our DNA. We are actively shaping the future of Industry 4.0 through our work in various associations, and we are involved from the start when new standards are defined. To date, IO-Link, ASi 5, and advanced physical layer (APL) are all topics that we've engaged with. We have also identified new sales opportunities that will emerge from widespread use of distributed 5G-enabled wireless sensors. These sensors will provide a comprehensive image of the physical world and help our customers better plan and control a huge range of production processes. I would say our objective is a healthy mix of research and entrepreneurship (laughs).

Dr. Werner ThorenWe call ourselves the 'people for process automation' so we are always asking our customers what will help them optimize production, increase plant availability, and ensure safe operation of plants now and in the future. We are seeing a trend toward more sensor technology and increased use of existing data. This idea is also being promoted by NAMUR, an important user organization in the process industry, via the NAMUR Open Architecture. The non-public 5G networks with a defined quality of service primarily offer the flexibility and reliability for these concepts to be implemented in our customers' highly distributed plants. Our objective is to work with our customers to make full use of the technology's potential and to ensure appropriate standardization.

Dr. Christian BauerFrom the very beginning, TRUMPF was actively involved in topics such as networked production and Industry 4.0. So it was a logical choice for us to support and help shape the technologies required for this production change early on. 5G has great potential to become a key enabler for data communication in production environments. The associated benefits are very diverse and include the ability to reduce the complexity of existing solutions, retrofit brownfield environments, and develop brand new applications with enhanced flexibility due to quick wireless communication. However, to be successful in this environment, 5G must satisfy requirements for industrial data communication. This is why TRUMPF, like Endress+Hauser and Pepperl+Fuchs, is a member of the 5G-ACIA—to help shape the 5G standard in line with industrial requirements in close collaboration with the world's leading ICT companies.

Dr. Werner ThorenSince digital communication became possible, Endress+Hauser has supported open standards to allow our field devices to be seamlessly integrated into our customers' systems. Together with Pepperl+Fuchs, we were one of the first providers to enable wireless communication via WirelessHART® products. We now use Bluetooth® to operate and parameterize field devices, and to read out data using mobile devices. Wireless communication has also always been key for distributed measuring points in logistics and supply networks. We now offer a simple, autonomous level measuring instrument that integrates with the Endress+Hauser cloud solution 'Netilion' and delivers information via the NB-IoT standard at the touch of a button. It's a genuine IIoT solution driven by customer applications. 5G will allow us to better serve more of these applications in the future.

Dr. Christian BauerStandardization of 5G will take time. Over several release cycles, specific aspects of the new standard are being defined by 3GPP (the standard development organization for wireless communications). TRUMPF is obviously following the progress being made, is actively shaping the standard via involvement in the 5G-ACIA forum, and is already working on various research and funding projects on the topic. We think it's important to build up the required knowledge early on so that we can use it as soon as appropriate technologies and hardware become available.

Benedikt RauscherAs I mentioned earlier, Pepperl+Fuchs has been working with wireless sensor technology for a long time. For example, we are developing battery-operated ultrasonic sensors, which transmit fill levels via wireless technologies. 5G offers us even more potential for this in the future. Our process automation division is also closely following the development of 5G. We already offer a comprehensive portfolio of industrial and explosion-protected mobile devices. In the future, 5G data transfer speeds will allow service technicians in the field to use an augmented reality app on their Ex-smartphones to view maintenance instructions for components in ultra-high definition and without lag. In addition, we are currently considering setting up our own frequency range at our headquarters in Mannheim as a means of looking into the topic and testing new application scenarios in more detail.