January 24, 2023

On the Right Frequency—LoRaWAN as the Future of Fill Level and Water Level Monitoring

The radio-based LoRaWAN ultrasonic sensor “WILSEN” from Pepperl+Fuchs solves a wide range of applications in waste management and flood protection.

Start of a Success Story

Sustainable innovation is a term that has several dimensions from a company’s perspective—it encompasses the positive environmental impacts of a product or solution, while ideally there should also be significant economic potential. The WILSEN.sonic.level or ‘WILSEN’ from Pepperl+Fuchs is an innovation that successfully combines both of these aspects. Behind this distinctive name (short for Wireless Sensor Node) is a radio-based LoRaWAN ultrasonic sensor that is attracting great interest throughout Germany and is on the way to becoming a standard solution in the field of waste management. But this IoT level sensor can also cover a wide range of applications beyond waste management—and even become a potential lifesaver.

As with many successful product developments, economic sustainability was not a sure-fire success with WILSEN, as Daniel Möst, New Business Development Manager at Pepperl+Fuchs, explains: ‘Today’s WILSEN is the result of continuous development. We have continuously gathered experience and feedback from customers and worked this into the product to create the solution that is available as standard today.’ In fact, the Mannheim-based specialists in automation technology already tested radio-based ultrasonic sensors in the field in 2014, as part of a smart city project in Barcelona. ‘At the time, it was already clear that the topic of sustainability would assume great global relevance one day. This trend has intensified further in subsequent years, and we have been able to implement a whole series of follow-up projects in other locations,’ says Möst, outlining the origins of WILSEN.

From Barcelona to Heidelberg

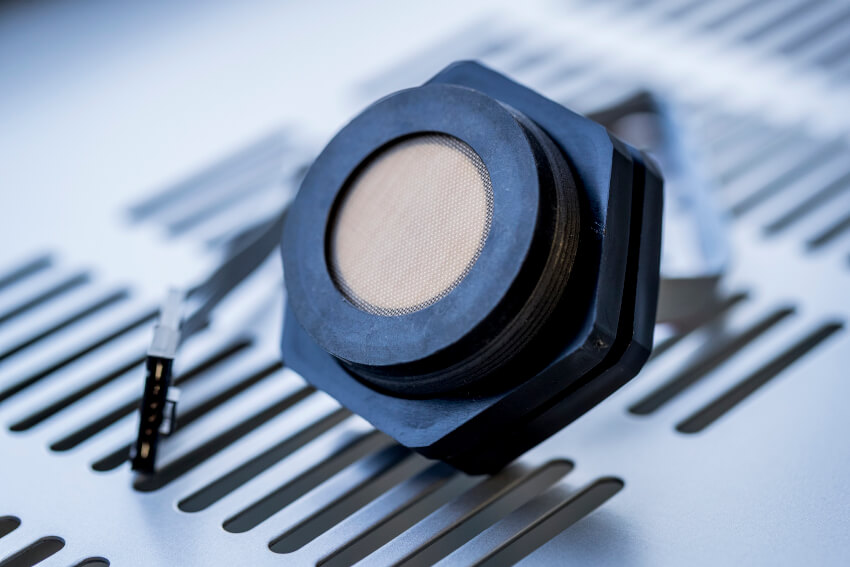

One of these follow-up projects took place near the Pepperl+Fuchs headquarters in Mannheim, marking another milestone on the way to series production. In conjunction with the Digital-Agentur Heidelberg, SAP, and Smart City Solutions, Pepperl+Fuchs designed a solution in 2018 for transmitting the fill levels of waste disposal containers in Heidelberg’s metropolitan area to an IoT platform via LoRaWAN using radio-based sensors. ‘For this purpose, we encapsulated an ultrasonic sensor—the transducer of which is coated with a PTFE protective film—together with a radio module and a battery unit in a special IP66/67 housing,’ says Möst. ‘This meant that the sensor technology had a robust design for the adverse ambient conditions in the waste disposal containers.’

The successful test runs showed that Pepperl+Fuchs was about to bring a product with great potential to series production maturity. What was still in its infancy under the simple working title ‘IoT sensor’ at the time, reached the wider market of public utilities and waste disposal companies shortly afterward with the catchy name ‘WILSEN.’

Intelligent Waste Disposal in Freiburg

Today, several years later, WILSEN has become an indispensable part of an ever-growing number of waste disposal containers throughout Germany. Freiburg im Breisgau is also part of the list of cities and municipalities that have discovered the battery-operated ultrasonic sensor from Pepperl+Fuchs. Around 350 glass containers throughout the entire metropolitan area require regular collection and emptying by ASF (Abfallwirtschaft und Stadtreinigung Freiburg—Freiburg’s waste management and city cleaning service provider).

To be able to act as efficiently and sustainably as possible, ASF has been relying on the support of badenovaNETZE for several years. As a subsidiary of badenova, it supports municipalities and service providers such as ASF in implementing IoT solutions, and has established a high level of expertise and understanding of quality in the field of sensor technology. For this reason, in Freiburg they also rely on WILSEN from Pepperl+Fuchs: In 2020, 50 of the radio-based ultrasonic sensors went into operation in the local glass containers, followed by another 50 units. “Each additional container that we equip with sensors from Pepperl+Fuchs helps us to further improve the database for pattern recognition and interpretation,” explains Sascha Dachtler, responsible for sales and project development at badenovaNETZE. ASF is already able to detect seasonal trends in container utilization and, thanks to the GPS data transmitted by the WILSEN sensors, to improve manual route planning.

Reduced Emissions Thanks to Optimized Routes

The additional smart containers promise great potential for further route optimization, especially in the less frequented suburbs that can only be reached by disposal vehicles driving longer distances. ‘Of course, the citizens of Freiburg are the ones who will primarily benefit from the smart containers. In the future, we want to implement fully automated route planning together with ASF. In this way, emissions and traffic obstructions in the metropolitan area can be reduced, and we can effectively counteract the annoyance caused by overflowing containers with the smart containers,’ says Dachtler. Due to its innovative character, this is also part of the ‘Smart Region Südbaden’ living lab project by badenovaNETZE and its cooperation partner Thüga AG. As part of this project, various smart city application examples have already been developed for various municipalities in the areas of mobility, buildings, environmental protection, and technical operations. ‘This gives us the opportunity to experience the added value of smart city applications for the participating municipalities and to promote the exchange of knowledge,’ emphasizes Dachtler.

Exchange between Industry Experts

WILSEN was chosen in Freiburg thanks to a tip from a former project partner who had already had a positive experience with the ultrasonic sensor and recommended it to badenovaNETZE. ‘We were looking for a truly robust sensor that uses our preferred, globally standardized LoRaWAN technology, reliably transmits fill level data even in varying ambient conditions, and can get dirty and wet from time to time. WILSEN promised to be a viable solution here,’ says Dachtler, describing the considerations made when choosing a sensor.

WILSEN also impressed in practice, as hoped by badenovaNETZE and ASF: “Each sensor is attached to a mounting base at the factory so that the devices can be screwed into the inside of the containers and be resistant to vibrations. This will help to prevent problems during emptying operations. Commissioning and logging into the LoRa network can be carried out easily via Bluetooth using an app from Pepperl+Fuchs. Once the sensor has started working, it is able to transmit measurement data over several kilometers via LoRaWAN despite shadowing from buildings or vegetation—all with very low battery consumption,” says Dachtler, describing the technical advantages of WILSEN. The support provided by Pepperl+Fuchs was an additional factor when selecting the sensors: “It was important for us to know that, if support was needed, we would not be connected to a hotline, but that the technician would be on-site at short notice. The support we received during the implementation phase showed us that with all these requirements, we had made the right choice with Pepperl+Fuchs.”

The successful project team shows the basic components of the intelligent disposal solution.From left to right: Daniel Möst (Pepperl+Fuchs), Sascha Dachtler and Paul Spies (badenovaNETZE), Timo Hähnert (Pepperl+Fuchs).

Existential Threat on the Banks of the Wupper

But WILSEN has also managed to tap into a highly satisfied user group away from the waste management industry—for example, at the Berger Gruppe in Wuppertal. However, the circumstances that led to the specialists for CNC robot grinding and polishing technology using the sensor were much more dramatic than in Freiburg. During the night of July 14 to 15, 2021, the Wupper River turned into a raging torrent after hours of heavy rainfall, flooding the Berger Gruppe’s company premises located not far from the river bank. ‘I was afraid that we would lose the company. The events still haunt me to this day,’ says Managing Director Dr. Andreas Groß, remembering the night of the flood with horror. ‘Our company premises spans 8000 m², of which 7000 m² were under water. This also affected 30 robots, which were awaiting outbound delivery to customers. Because we have always been denied insurance against flood damage due to the problematic location of the building, we ultimately had to cushion a loss of almost a million euro ourselves,’ says Groß, outlining the scope of the disaster.

Willingness to Take the Initiative

In retrospect, the PhD engineer is critical of the public monitoring and protective measures at the time of the flooding: ‘In the age of digitalization and climate change, a few sensors that are not networked with each other and an incomplete network of sirens cannot be the requirement for a reliable flood warning system,’ says Groß. And so—even during the debilitating cleanup work—a plan formed within the Berger Gruppe to develop a technical concept to protect people and buildings along the Wupper River and its tributaries more effectively from flood events in the future: ‘Simply complaining about fate was not an option for us. Instead, we considered what impetus we could provide to the general public as a company with technological expertise.’

The Berger Gruppe can draw on extensive expertise in the fields of sensor technology, control technology, and adaptive learning. This is evidenced by the 950 robot automations that the company has realized for its customers over the years. This knowledge has now also been incorporated into the development of the initial technical requirements profile for a monitoring and analysis system, with which water and rainfall levels along the Wupper, its streams, and other inlets can be reliably monitored.

Precisely Matched Sensor Technology

A key aspect of the concept was, of course, the sensor technology to be used: ‘Choosing a suitable sensor solution was a subtopic that I took care of myself. During my research, I became aware of the WILSEN ultrasonic sensor from Pepperl+Fuchs, which already covered many of our required criteria,’ explains Groß. One of the aspects that convinced him was the adjustable transmission intervals: ‘In the software, we can now synchronize the transmission behavior of the sensor with the current weather data. This means that in the event of reported rainfall, WILSEN transmits fill level data to our server more frequently via the LoRa network than in fair weather conditions. This allows the runtime of the high-power batteries to be extended even further,’ explains Groß.

Nevertheless, Groß and his colleagues had a special adaptation request for Pepperl+Fuchs: ‘The standard sensing range of WILSEN is certainly completely sufficient for monitoring a waste disposal container. However, since we often mount the sensors on or under bridges and these have varying heights, we did not want to risk the distance between the bridge and river bed being too large for the sensor in some cases. We discussed this with Pepperl+Fuchs and they fulfilled our request, and the detection range of the sensor has been significantly increased. This really impressed us and showed us that we are relying on the right partner for ultrasonic sensors.’

Sensor Data as the Basis for Adaptive Learning

Since then, the project on the river Wupper has continued to gain momentum—in addition to the Berger Gruppe, Stadtwerke Wuppertal, Technische Betriebe Solingen, Bergische Gesellschaft, the University of Wuppertal, and the associated IZMD (Interdisciplinary Center for Machine Learning and Data Analytics) are also supporting the ambitious project. Around 60 WILSEN and additional pressure sensors are now operating along the 116-kilometer-long stretch of water. ‘Monitoring water levels with sensors is not unchartered territory, but what we are doing with our project is going further than before. We are using the measurement data to feed and further develop the data-based, adaptive learning system of the IZMD. In two to three years, we will be able to make highly accurate predictions regarding the development of water levels using an algorithm. The combination of radio-based sensor technology and artificial intelligence that we work with here is a perfect match for this,’ says Groß optimistically.

Furthermore, Groß and the other supporters hope that their prototype development will be included as a flagship project in the top AI cluster in North Rhine-Westphalia. ‘That would of course give our project a big boost. In the future, we would like to provide a scalable and low-threshold flood warning system based on an open source principle, from which not only the residents of Wupper, but also the wider public can benefit,’ says Groß, outlining the long-term goals. The project has long since attracted the attention of this very public. This is supported by the fact that Groß recently even received an interest request from the US state of Mississippi, which is very familiar with floods.

Dr. Andreas Groß presented the ambitious flood protection project to the public at a press conference. (Image courtesy of the Cronenberger Woche)

Transferable Principle

Meanwhile, Pepperl+Fuchs is also busy with regard to the future of WILSEN. More and more industrial customers have now discovered WILSEN for themselves, as Daniel Möst from Pepperl+Fuchs describes: ‘We are currently implementing WILSEN at a major car manufacturer in South Germany, for example. Monitoring IBC tanks or recycling containers on the plant premises harbors considerable potential for optimization that can be leveraged with relatively little effort. Radio-based ultrasonic sensors have now proven to be an ideal solution for various applications in the context of sustainability, smart city applications, and in industry.’

Furthermore, on the basis of all the project experience gathered, the company continues to develop the basic idea: ‘Next, we will also combine sensing principles other than just ultrasound with radio transmission. Our customers and users can already look forward to another version of WILSEN—with the WILSEN.valve we are planning to enter the market with a battery-powered LoRa sensor for valve position monitoring. We see a great need in this area and we are convinced that we will be able to offer a tailor-made solution in the near future,’ concludes Möst.