March 13, 2023

Freight Measurement 2.0

With the aim of digitalizing measuring tasks in the logistics sector, LASE Industrielle Lasertechnik GmbH is developing laser-based systems for automated freight measurement. In these applications, the R2000 LiDAR sensor from Pepperl+Fuchs enables high-precision 3-D measurements within seconds.

Whether sending standard pallets, oversized freight, or other general and bulky goods, every company that ships products benefits from being able to measure cargo dimensions as accurately as possible. Accurate measurements not only mean that freight costs can be precisely calculated, but they also allow the loading of trucks to be optimized to ensure that the limited space in the truck is used in the ideal way.

In many companies, freight measurement is still carried out manually. 'Measuring the pallet by hand with a folding rule, writing the numbers on a piece of paper, and typing them into the PC—a process as complex as it is prone to errors,' comments Lars Ambrosy, Managing Director of LASE Industrielle Lasertechnik GmbH. To digitalize this process, his company has developed systems for automated freight measurement—with the support of LiDAR sensors from Pepperl+Fuchs.

Leaving Behind Pen and Paper

LASE specializes in solving a wide range of industrial applications with laser technology. For this purpose, the company uses its own application-specific software to apply further processing to raw data from laser sensors. The company, based in Wesel, North Rhine-Westphalia, Germany, has been well-known in ports, steel mills, and mining operations since the 1990s. 'About five years ago, we began to gain a foothold in the logistics sector,' says Ambrosy. 'We wanted to use the technologies that we have been using on a large scale for a long time in the port sector for similar measuring tasks in logistics.'

The advantages offered by automated freight measurement are obvious to the Managing Director of LASE: 'Digitalizing the processes means that freight can be measured without any need for manual recording or data entry. This minimizes the work involved and the likelihood of errors, and also increases traceability.'

Measurement Results in Seconds

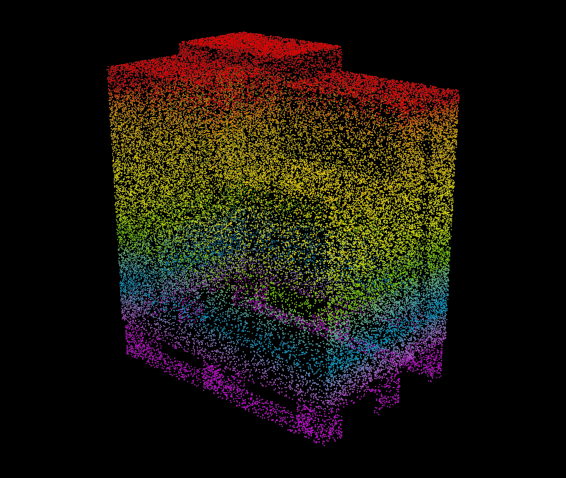

To enable fully automated measurement of pallets and other freight items, LASE has developed a series of systems called LaseAFM. 'These systems use the R2000 LiDAR sensor from Pepperl+Fuchs to generate a 3-D point cloud image of the object being measured. From this, the dimensions and volume of the freight are determined to an accuracy of +/- 20 mm. This data can be automatically fed into the merchandise management system,' explains Ambrosy.

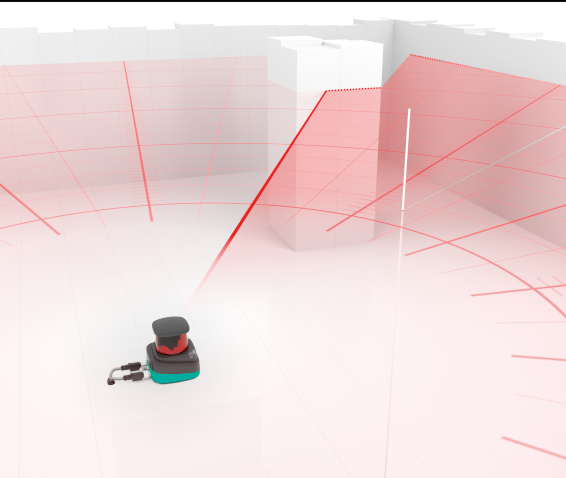

The LaseAFM-2-MB, an especially innovative system from the LaseAFM series, is used when pallets or other cargo items are measured on a measuring surface on the ground. A measuring beam is mounted diagonally above the surface, suspended from the ceiling, for example, and a LiDAR sensor is mounted in a swivel unit at each of the two ends. 'The laser scanners are rotated once from left to right by a servo motor, therefore capturing all sides of the pallet. In combination with the movement data from the swivel unit, an evaluation unit determines the volume requirement within a few seconds,' says Ambrosy, summarizing the function principle.

The design of the LaseAFM-2-MB offers numerous benefits compared to other solutions on the market, according to Ambrosy. Since the measuring beam is suspended from the ceiling, there are no metal parts that could obstruct the passage of forklifts or material handling equipment. Unlike systems based on a square frame with two linear units, the LaseAFM-2-MB is characterized by an especially high degree of efficiency and low weight: "Because we only need one measuring beam, our system is easier to install, easier to maintain, and less prone to failure."

Highest Resolution, Compact Design

When laser measurement technology specialist LASE began to develop its freight measurement systems, the selection of the appropriate sensor technology played a decisive role. To measure pallets quickly and precisely in 3-D, sensors were needed that offered the right resolution. Another challenge was posed by the poorly reflective black plastic film that is often used to wrap pallets.

In search of the appropriate sensor technology, LASE turned to Pepperl+Fuchs. For freight measurement automation, Business Development Manager Arno Hagemann recommended the use of the R2000 2-D LiDAR sensor: 'This sensor is characterized by a small light spot in combination with the highest angular resolution in its class. It offers an exceptionally high pixel density—with a compact design and a weight of only 800 g.'

Optimized for Specific Requirements

Ambrosy explains in more detail why these features were of particular importance for the LaseAFM-2-MB system: 'The high scanning frequency of the R2000 allows for quick measurement, while the small light spot ensures precise scanning. This allows us to accurately capture the dimensions of the freight in a few seconds. The sensor's low weight is also an advantage, because we were able to keep the servo motor system in the swivel unit small.'

However, not all requirements of the application were met from the outset—the ability to detect black packaging film was a particular challenge. 'When the request arrived from LASE, we had already started development of a new version of the R2000,' recalls Hagemann. 'To make the application requested by LASE a reality, we optimized the new version to give it a very wide detection range on black surfaces.' This range on the new OMD60M model has been doubled in comparison to the standard model. 'Although the black film reflects only three to four percent of the light, that still results in a detection range of about eight meters, which is completely sufficient for measuring freight,' Hagemann calculates.

Ambrosy looks back positively on the cooperation with the Mannheim-based automation specialist: "It wasn't long before Pepperl+Fuchs provided us with a prototype that we were able to test in the application. The sensor has demonstrated the perfect properties for detecting black packaging film. In addition to its high resolution, compact design, and economical price, this was a major reason why we chose the R2000."

Wide Range of Uses

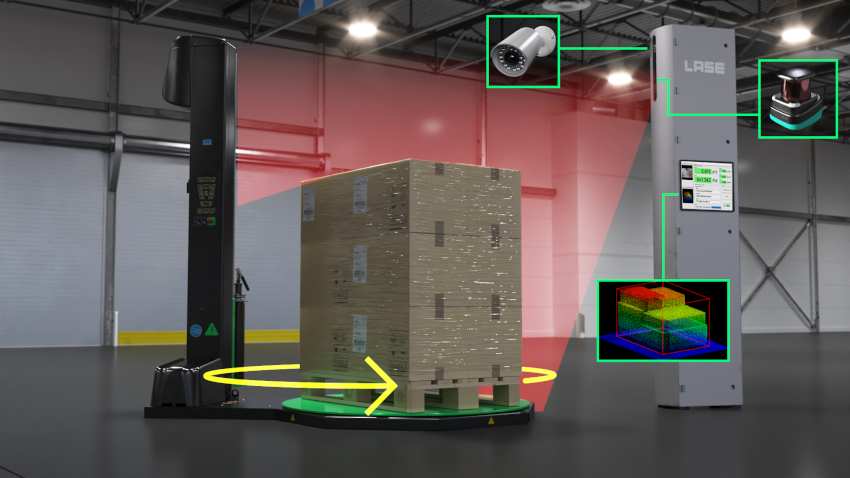

LASE also relies on the 2-D LiDAR sensor from Pepperl+Fuchs for other automated freight measurement solutions—the LaseAFM-Tower system, for example, which is intended for use on semi-automatic wrapping machines. The pallet is placed on a turntable and wrapped in film to secure the load. The OMD60M version of the R2000 measures the pallet during the rotating process. A single sensor is therefore able to capture all sides of the pallet.

"This form of freight measurement is especially time-saving because the measurement takes place at the same time as the wrapping process," explains Ambrosy. According to him, the R2000 from Pepperl+Fuchs has been able to prove its worth in this system just as on the Lase-AFM-2-MB—not only because it has a high detection capability for black plastic film, but also because its compact design makes it easy to integrate into wrapping machines.

Toward the Logistics of the Future

The freight measurement systems from LASE have now been available on the market for over five years. For Sales Director Lars Mohr, the story so far has been a success: "We only have satisfied customers—and we are noticing that interest continues to grow." As Mohr emphasizes, this is because automated freight measurement offers enormous potential for the future. "Digitalization in logistics is only just starting to take off. We are driving forward this process with our automated freight measurement systems and helping to reduce the manual workload for companies and make the entire process as efficient as possible."