March 8, 2018

Safety Revolutionized

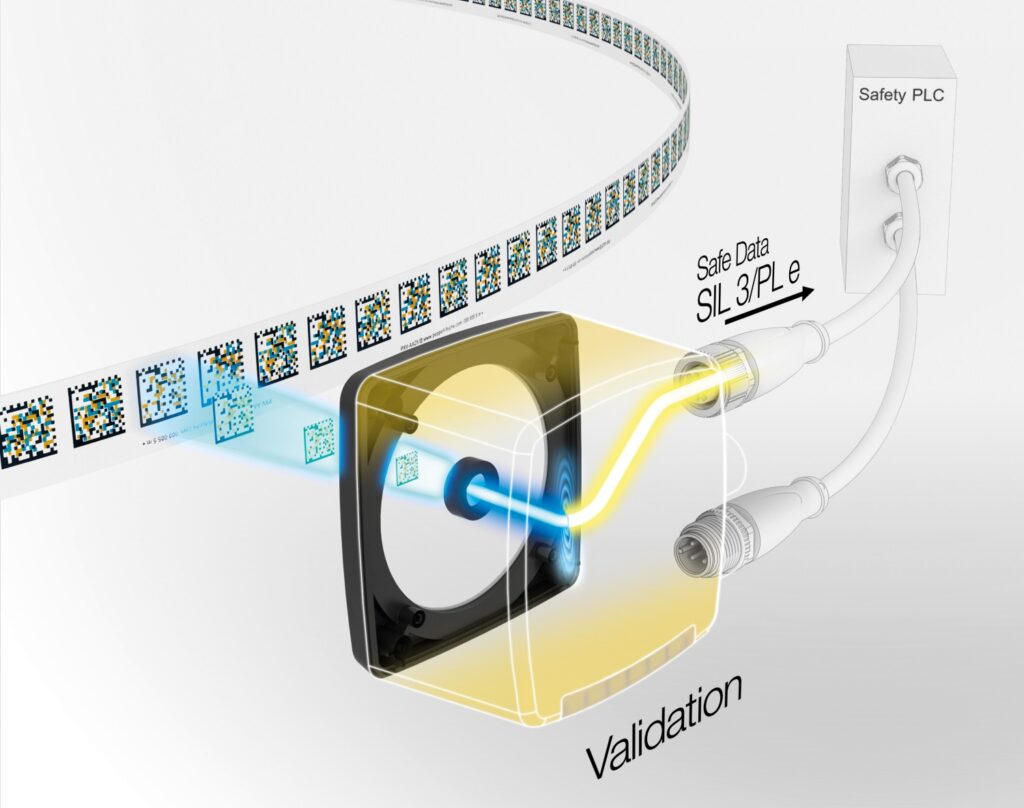

For the first time, the Pepperl+Fuchs team has made SIL 3/PL e-compliant safe absolute positioning possible with a single sensor. Get insights into the development of the latest generation of positioning systems safePXV and safePGV.

“No risk, no reward,” says Armin Hornberger, head of product management for industrial vision components at Pepperl+Fuchs. Holding up safePXV and safePGV, the new generation of positioning systems, he adds with a smile: “Developing these modules was a special kind of challenge.” But it paid off in the end: For the first time, Hornberger and his team have made SIL 3/PL e-compliant safe absolute positioning possible with a single sensor.

Safety has always been an important topic for plant operators—even more so since EU Machinery Directive 2006/42/EG took effect in December 2009. Whenever humans and machines work together, even the smallest risks must be minimized to ensure everyone´s safety. “Especially in factory automation, functional safety is becoming more and more important,” explains Hilmar Hofmann, head of development for industrial vision components at Pepperl+Fuchs. “To meet these market requirements, it was clear that we had to add safety functionality to our standard positioning systems.” As head of development, Hofmann has been involved in safePXV and safePGV from the very beginning. He and Hornberger take a look back at the highs and lows of their long journey from idea to finished product.

It´s Not Easy Being First

“Without a doubt, the biggest challenge of this project was creating a concept and getting it approved by TÜV,” says Hornberger, referring to the German technical inspection association. “Along the way, we played through countless scenarios, built and tested prototype after prototype, only to scrap them after consultation with TÜV.” “That is par for the course when you are the first manufacturer to bring this kind of system to market,” adds Hofmann. “We had a lot of ideas and attempts that TÜV did not approve. But the development team learned from every setback until we ultimately overcame the obstacles and developed a SIL 3/PL e-compliant single-channel camera system.”

A True Innovation—in More Ways than One

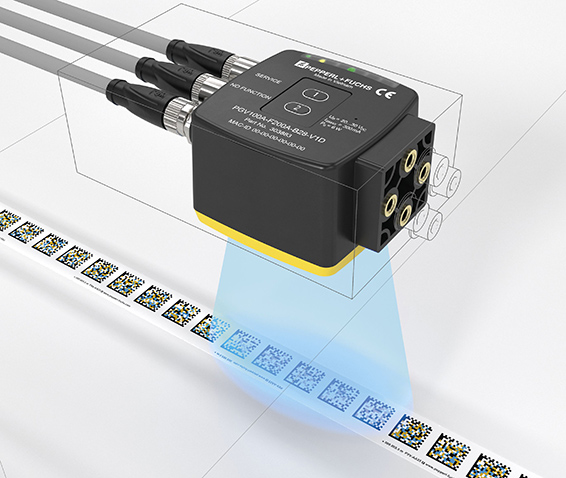

How was Pepperl+Fuchs able to reach this level of safety with just one sensor? “The combination of a multi-color Data Matrix code and two-color LEDs in the read head was the key,” explains Hofmann. “The code tape has two superimposed Data Matrix codes, one red and one blue. And the 2-D camera is equipped with red and blue LED rings that enable the new absolute positioning systems to read the different codes separately.”

Unique firmware serves as the positioning systems´ control center. It checks the plausibility of all data with a safe algorithm directly in the sensor and sends safe data via a PROFINET PROFIsafe interface to the safety PLC. “This allows position data to be processed in accordance with SIL 3/PL e immediately and without additional function blocks,” says Hornberger. “Achieving this level of safety used to be complex and costly, but safePXV and safePGV make it easier than ever.”

Perfecting a Tried-and-Tested Technology

The new positioning systems are based on proven sensor technology that has its roots in Pepperl+Fuchs´ position coded vision system, or PCV for short. Introduced in 2011, PCV revolutionized the positioning market with an innovative combination of 2-D camera and Data Matrix code tape. This technology, still unique today, was then expanded to create position guided vision, or PGV, which is used to navigate automated guided vehicles. Looking back, Hornberger says: “We have solved countless applications and gained a lot of application expertise with these two modules. Our new safety solution reflects all of the customer feedback that we have gathered throughout six years of field experience.”

Compared to its predecessors, the latest generation of positioning systems has a larger reading window that can read up to five Data Matrix codes simultaneously. The codes themselves are also four times larger. “In practice, this provides multiple redundancy,” says Hornberger. “The expanded reading window and large, redundant Data Matrix codes make the system fail-safe. This ensures reliable positioning at all times, even when codes are damaged or contaminated—which often happens in outdoor applications, for instance.” This multiple-redundant technology makes safePXV and safePGV the most reliable positioning systems on the market today.

Designed with Help from Customers

“Customer feedback is what fuels our work,” says Romina Schnabel, one of the product managers for positioning systems at Pepperl+Fuchs and a new addition to the project team. “This is the only way we can adapt our products to the requirements of different application areas, which are as varied as the technology itself.”

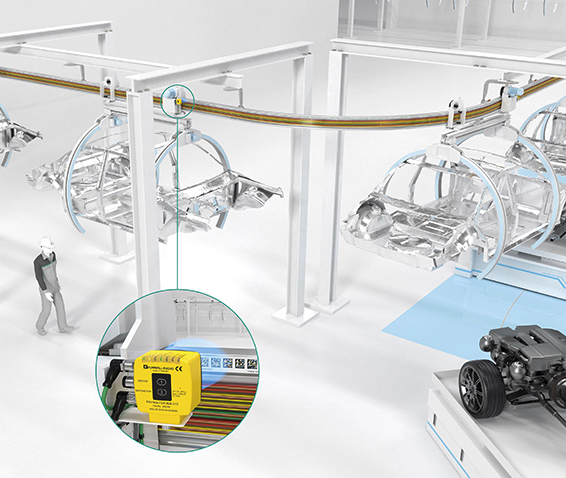

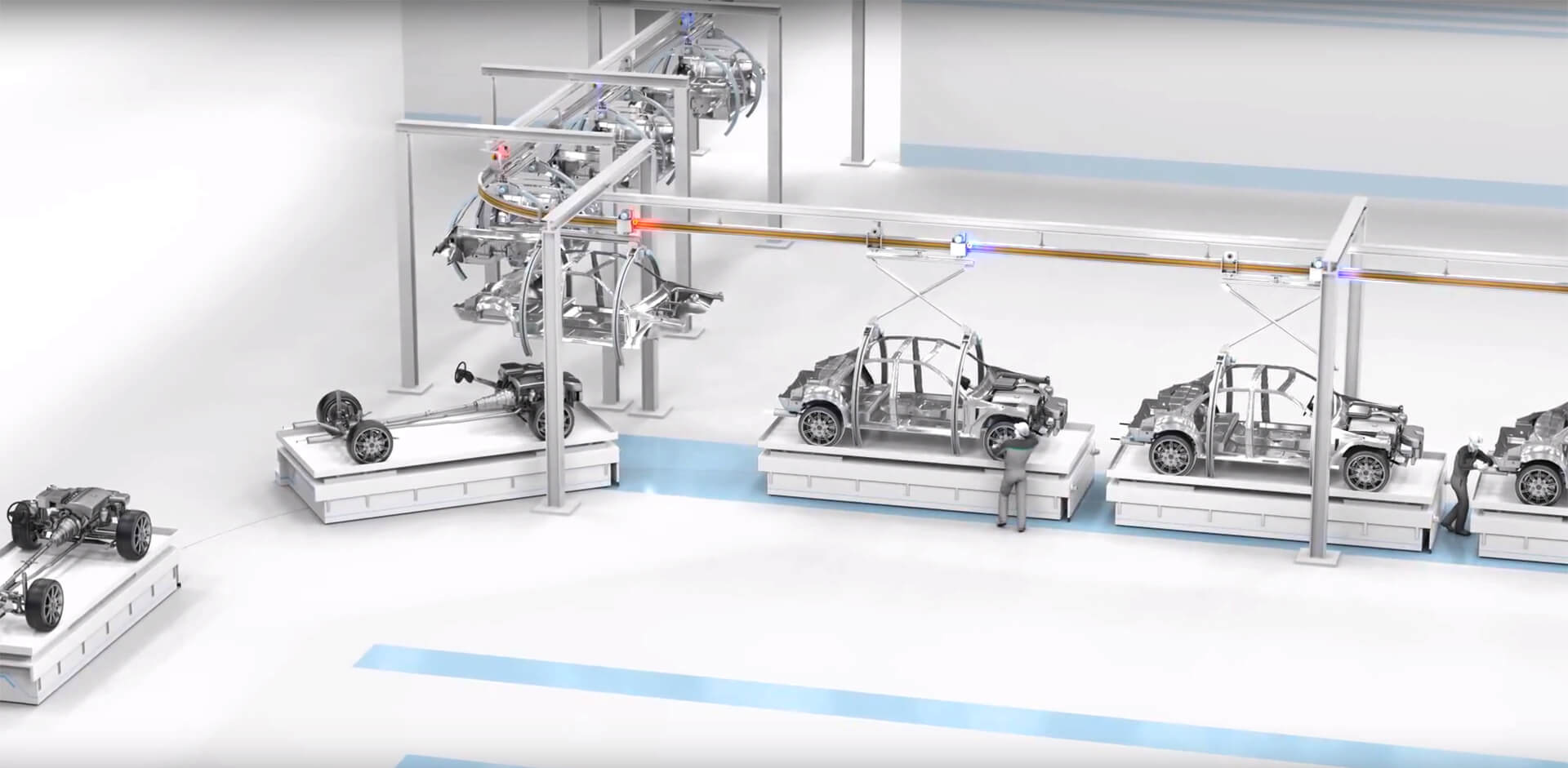

Designed for linear absolute positioning, safePXV can be found on monorail conveyors, stacker cranes, rotary tables, elevators, and wind turbines. “Considering the variety of applications, ease-of-use is certainly a key benefit,” says Schnabel. The wide reading window and large depth of focus make time-consuming, precise camera configuration unnecessary. “Assembly is as quick and straightforward as you can imagine,” sums up the product manager.

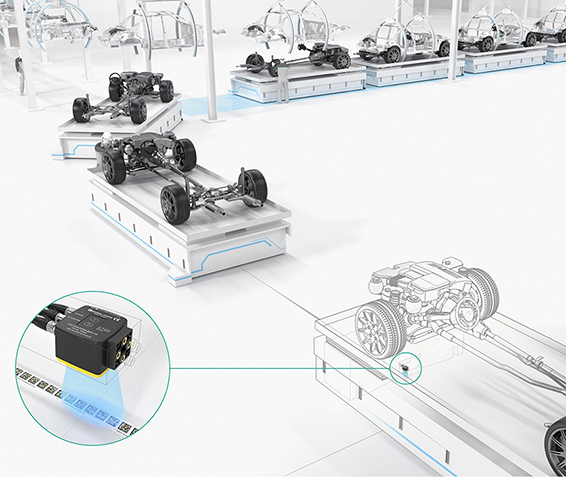

safePGV goes one step further. In addition to absolute positioning, it also provides all data needed for reliable control of automated guided vehicles (AGVs). By transmitting the Y position and angle, safePGV allows continuous correction of track deviations. And the safe X position ensures that a safety distance between AGVs is maintained to keep personnel out of harm´s way.

Both systems are designed to handle tight curves and slopes, and gaps in the code tape up to 75 mm long will not affect performance in any way. “This is especially useful on longer routes when expansion joints in the building have to be bridged,” says Hornberger. “This is another example of an optimization that resulted directly from real-world requirements of our customers.”

“Music to My Ears”

Perseverance, a spirit of inquiry, and a healthy dose of confidence were the key success factors for this project. “From the developers to our colleagues in production to marketing and sales—the whole team pulled together,” says Armin Hornberger enthusiastically. The new safePXV and safePGV positioning systems were introduced last November at the SPS IPC Drives trade show in Nuremberg. “The initial reactions were very positive,” says Hilmar Hofmann. “‘Hats off, your competitors are not going to like this´—that response was my personal highlight,” adds Romina Schnabel. Hofmann agrees: “After all the work we put in, that was music to my ears.” When asked what the future holds, it is clear that the team´s enthusiasm has not faded. “First of all, we are still faced with challenge of integrating additional interfaces such as CIP Safety and FSoE in the sensor housing. Otherwise, we are already working on new ideas with Industry 4.0 in mind,” promises Hornberger.