Dec 4, 2018

Beauty and Brains

Heidelberg is on its way to becoming a "Smart City" and relies on special ultrasonic sensor technology from Pepperl+Fuchs.

Historic, picturesque, cosmopolitan, dreamlike, or simply romantic. These are all words commonly used to describe Heidelberg, the beauty on the Neckar. And now another word is finding its way onto the list: "smart"! After all, despite its wonderfully picturesque backdrop, Heidelberg is a major city—with all of the associated infrastructural and administrative services. For the benefit of its 160,000 residents and almost 12 million annual visitors, Heidelberg recognizes the need to make use of smart technology to create a more digitalized approach to its city services.

Prof. Eckart Würzner, Mayor of Heidelberg, has a clear goal in mind: "We need to get to a point where digital infrastructure is an integral component of public services—just as we see with electricity, gas, or water." Keen to press ahead with Heidelberg's quest to become a "smart city" and inspired by the concept of an Internet of Things, the city even created an organization in 2017 designed to achieve just that—Digital-Agentur Heidelberg GmbH. The organization works actively with partners from the research and business communities to drive a variety of projects in the heart of Heidelberg.

Enhancing Quality of Life

Digital-Agentur worked closely with experts from SAP Digital Business Services to identify, analyze, and evaluate the first tangible smart city applications. Various scenarios were discussed and their complexity and feasibility analyzed at a design-thinking workshop at the creative hub SAP AppHaus in Heidelberg.

The newly-founded agency decided to launch a pilot project to digitalize one aspect of the waste management service. "With REMONDIS and AVR Kommunal GmbH, we have two future-oriented service providers at our side who have been directly involved in brainstorming scenarios. If we could get data about fill level from inside waste disposal containers, it would be possible to plan the routes of waste collection vehicles in the city of Heidelberg much more efficiently. This would benefit the residents, the city, and the waste management companies," says Sebastian Warkentin, Managing Director of Digital-Agentur.

His colleague Ruben Roque, who is responsible for strategic business development at the organization, explains the benefits of smart waste management in more detail: "If waste management workers are able to take more efficient routes, they will save time and reduce wear on their vehicles. The entire process can be planned much more precisely in advance, and the city of Heidelberg and its citizens will benefit from on-demand waste collection, reduced noise, reduced exhaust emissions, and fewer overflowing recycling containers."

Shared Expertise in Baden-Württemberg

Working together to manage the ambitious project, Digital-Agentur and SAP Digital Business Services opted for the kind of agile approach that is typical of innovation projects. "Our approach to this project is characterized by iteration cycles based on the ‘fail early and fail often’ principle,” explains Pascal Matt, solution architect at SAP Digital Business Services. The industrious networkers from Digital-Agentur set about finding the additional partners required for the project and struck gold in their own backyard: "We needed a true specialist in sensor technology to help us gather status data from inside waste disposal containers, which is why we approached Pepperl+Fuchs in Mannheim. The data gathered by the sensors is transferred to the city of Heidelberg via a new and specially designed wireless sensor network. Karlsruhe-based Smart City Solutions GmbH contributed insight based on its practical experience in integrating supplier-specific applications such as this," says Warkentin. Once the data has been extracted through this channel, it is processed and interpreted using software solutions from Walldorf-based SAP SE before being made available to all stakeholders. "This collaborative project underscores the level of IIoT technical solutions expertise that is available in the Baden-Württemberg business community and clearly illustrates how companies can work together for the benefit of the city," explains the Managing Director of Digital-Agentur.

Flexible Ultrasonic Sensor Simplifies Integration

The interdisciplinary team of experts is now conducting trial runs in various locations both within and on the outskirts of Heidelberg. Many of the local residents are still unaware that they are indirectly helping to shape Heidelberg's digital future by simply making their regular trip to the recycling bin. "The sensor solution is attached to ten waste glass containers but isn’t visible from the outside. If you are intrigued by this idea and try to look for some wiring, I'm afraid I must disappoint you. The technology is battery-operated and completely wireless," says Pepperl+Fuchs’ Wolfgang Weber with a smile. The experienced global industry manager knows how to determine the requirements of specific industries and translate them into solutions with his colleagues in development and product management.

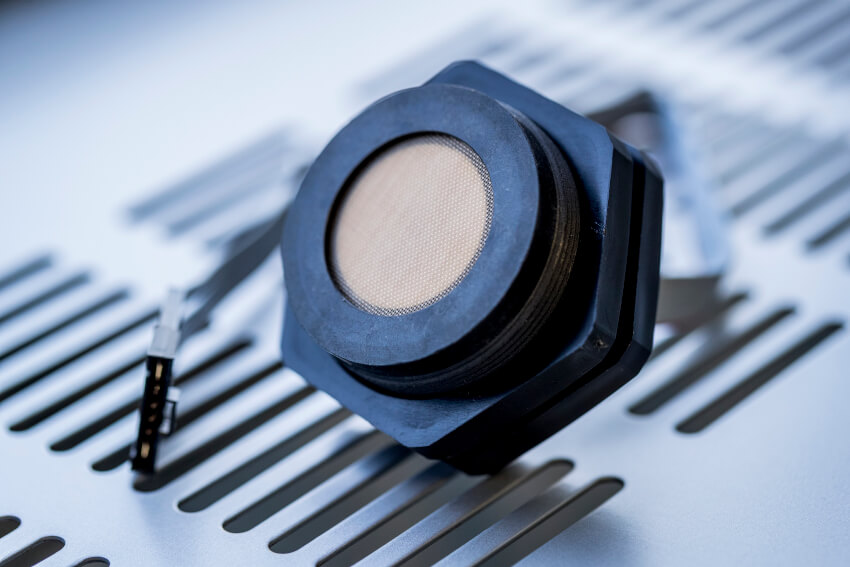

A special ultrasonic sensor is at the heart of the glass recycling container solution. "The UCC*-50GK is a modular ultrasonic sensor, which has been designed to support highly flexible and simple integration. In this particular scenario it is accompanied by other components selected specifically for the smart waste management application," says Till Hoffmeyer, product manager for ultrasonic sensors at Pepperl+Fuchs. For instance, a battery unit, an energy-efficient wireless module, and rugged housing are among the components working alongside the UCC*-50GK. Pepperl+Fuchs refers to this complete solution as an "IoT sensor." "Unlike conventional industrial sensors, the UCC*-50GK has been optimized for use in an IT environment. Our colleagues from Smart City Solutions in Karlsruhe are in their element when integrating the sensor into the application and completing the configuration process. They can utilize the full scope of their expertise without having to deal with time-consuming PLC programming," says Weber, illustrating the benefits for his partner. "Once the sensors have been configured, they can transmit their data directly to the IoT cloud via the wireless module," adds Hoffmeyer. Pepperl+Fuchs developers provided their colleagues at Smart City Solutions with three application-specific interfaces for integrating the ultrasonic sensors: LIN bus, UART, and PWM.

The ultrasonic sensor UCC*-50GK from Pepperl+Fuchs is the building block for the solution. It is optimized for use in an IT environment.

The combination of the ultrasonic sensor UCC*-50GK with additional modules turns into the "IoT sensor" which offers eight different functions.

In-House Development for Smart City Applications

Integrating the sensors was one of many factors that the market leader for ultrasonic sensor technology had to consider during development. As it turns out, the inside of a waste disposal container presents some unique challenges. "It quickly became clear to us that our solution had to be capable of extremely reliable operation for this IP66/67 application. We applied a PTFE protective cover to the transducer of the ultrasonic sensor, making it resistant to the corrosive chemical substances that can develop in a waste disposal container. The sensor operates within an ambient temperature range of -25 °C to +70 °C, and a built-in temperature compensation element prevents the sensor from being affected by temperature fluctuations. In addition, the sensor had to offer a high level of flexibility due to the unpredictable measuring environment. Project manager Ernst Luber and his team rose to the challenge. The sensor has adaptive measuring profiles that enable it to adjust to the prevailing conditions and detect a reliable fill level value within just a few measuring cycles," explains Hoffmeyer, speaking about the new solution from the Pepperl+Fuchs ultrasonic competence center in Amberg, Germany.

LoRa Connects Heidelberg

Fill levels are not the only thing the IoT sensor can detect. There are a total of eight functions, including measurement of GPS data and temperature values. Robert Koning, managing director of Smart City Solutions GmbH, explains how all this data is transferred to the SAP software solutions for further analysis: "Here in Heidelberg, we are currently testing a long-range wide area network (LoRaWAN). The network is designed to handle data transfer for digitalized public services like those found in the pilot project for glass recycling." The major advantage of this strategy is that LoRaWAN networks are extremely energy-efficient and cost-effective to set up and operate. Koning explains: "Just a single gateway or base station is sufficient to cover a huge area of the city. There's simply no comparison with conventional Wi-Fi technology, and this scope makes LoRaWAN ideal for these types of IoT applications in public spaces. The volume of transmitted data is low, as is the energy consumption of the connected end device." An IoT sensor from Pepperl+Fuchs can actually operate for years without maintenance or a single battery change, courtesy of the LoRaWAN and intelligent power management technologies used in the ultrasonic sensor (power save mode, bootloader, and sleep mode).

Intelligent Glass Recycling Collection with Cloud Technology

The cloud-based IoT solution SAP Connected Goods receives the data from the LoRaWAN network. It is configured specifically for use by the waste disposal scheduling team from AVR Kommunal GmbH. "AVR is a longstanding customer of SAP and is already using SAP Waste and Recycling, our solution for the waste management industry. The trust AVR has placed in us and our mutual curiosity about what the future holds provide an excellent basis for the consistent implementation of an IoT project such as this," says Dr. Frank Rambo, product manager for IoT solutions at SAP.

The user display shows a clearly structured dashboard interface. Rambo describes its functions: "Once the container has been onboarded, SAP Connected Goods displays the fill level of the container as a percentage, and the GPS data allows us to see the exact location of the individual containers on the map. By integrating the technology into our SAP Waste and Recycling industry solution, we can define rules to govern when a glass recycling container is considered full and can automatically arrange for the waste management provider to promptly empty the container. This means that the routes taken by the waste collection vehicles can be determined dynamically based on current requirements."

SAP Connected Goods also makes it possible to identify and evaluate trends and peak times for container use, as the individual measurements are time-stamped. "If a specific glass recycling container tends to get very full on Saturdays due to a regular sporting event, for example, SAP Connected Goods shares the information so that waste management companies can take the necessary action," explains Rambo. He also shares his thoughts about the reliability of systems like this: "Working together with our partners, we have created a system that is able to cope with the toughest demands. The IoT sensor from Pepperl+Fuchs has a robust design, and its advanced features ensure greater safety in the supply workflow. For instance, if there is a fire in a container, the integrated temperature probe will detect it right away. SAP Connected Goods allows us to define the appropriate temperature limit values and automatically send alarm signals to predefined contact persons. The system also displays the battery charge status and indicates potential errors when the ultrasonic sensor is obscured."

Smart Waste is one of several flagship projects intended to gradually shape and develop a digital Heidelberg.

Dr. Eckart Würzner, Mayor HeidelbergGreen Light in Sight

The project team, led by Pascal Matt on the SAP side, developed the first prototypes for the application within three months. The preconditions for securing a greener, digital future for Heidelberg are good in many respects—and work on the next steps is moving full speed ahead. Digital-Agentur Managing Director Warkentin sums up the outlook: "Following completion of the test phase, the project team will evaluate the final results and draw conclusions. Once this work is complete, we will present the details to various stakeholders from around the city. It is clear even at this early stage that we have found the right partners to help us roll out the smart waste management project on a larger scale."

Pascal Matt outlines the additional application possibilities: "IoT solutions like this one demonstrate that it will be possible in the future to network other containers, such as compacting containers, via wireless and wired sensors and to make them IoT-compatible. The data generated can be shared with the various divisions of our digital city and made available to service providers." At Pepperl+Fuchs, Wolfgang Weber is also eagerly awaiting the next steps: "As the sensor technology partner in the project, we are delighted to have played a key role in ensuring the success of this smart IoT solution. We will continue to support the project with our technology expertise."

Heidelberg Mayor Eckart Würzner is impressed by the initial results from the test phase: "Smart Waste is one of several flagship projects intended to gradually shape and develop a digital Heidelberg. Thanks to the outstanding collaboration between all of the parties involved, we are making excellent progress on fill level monitoring."

(Project Status: December 2018)