Water Analysis: From Impurities to Explosion Hazards

March 6, 2025

Process and wastewater must be closely monitored, as contaminated water can cause considerable damage to plants and the environment. Swan offers various analytical instruments for monitoring water circuits. In hazardous areas, a purged and pressurized enclosure solution from Pepperl+Fuchs ensures that these components do not represent a potential ignition source.

Water is used in many places in industry in different aggregate states and qualities—whether as cooling water, as vapor in cracking processes or as pure, demineralized water in the semiconductor industry, pharmaceutical production, and in electrolyzers for the production of green hydrogen. In the course of use, impurities inevitably occur, which must be analyzed and controlled in detail. Depending on the process and industry, there are different tolerance values for when the water must be treated accordingly before damage occurs in the system or contaminated water is released into the environment. Sampling and analysis often takes place in areas that are classified as potentially explosive. Appropriate explosion protection precautions are therefore essential.

Online Water Analysis—from Industrial Process Water to Water and Steam Circuits

Whether heavily contaminated or partially contaminated, such as reflux condensates, the water must sooner or later undergo treatment before it can be reused or discharged. This is where the Swiss company Swan Analytical Instruments AG comes into play as a manufacturer of online analytical instruments for the continuous monitoring of water quality. The company, based in Hinwil, near Zurich, is one of the world's leading suppliers of online water analysis systems. These analyze the levels of dissolved substances in water and transmit the parameter values directly to the process control system. Swan offers a wide range of solutions, from individual measuring signal converters and ready-to-use analysis monitor assemblies to complete container solutions for sample analysis. Swan's systems are used worldwide, especially in areas where water treatment plays a decisive role—for example in the quality assurance of ultrapure water in electrolyzers, in pharmaceutical and semiconductor production, and in the treatment of swimming pool and drinking water.

"Power plants and industrial plants with their steam production are among our most important target markets," says Nils Schwäbe, Product Line Manager at Swan. Classic applications include monitoring the reflux condensate. Process-related contamination of the steam condensate can lead to major damage in the systems. In certain processes, such as steam cracking in the chemicals and petrochemicals industries, the vapor also comes into direct contact with process media. Samples are continuously taken and analyzed to check when the reflux condensate needs to be treated externally.

Process-related contamination of the steam condensate can lead to major damage in the systems.

Environmental Protection—When the Sea Is Used as Cooling Water

"We also see significant growth potential with our analysis systems in other industrial applications and energy generation market segments. These include the production of green hydrogen, as well as the processing and transportation of liquefied natural gas (LNG) on FPSOs." FPSO stands for "Floating Production, Storage, and Offloading" and describes tankers that are used on the high seas for the production and simultaneous processing and transportation of crude oil and LNG.

"On FPSO tankers, seawater is also used for cooling and heating in various process steps," explains Schwäbe. To prevent algae growth in the tanks, heat exchangers and pipes used for this purpose, it is mixed with a biocide such as chlorine or produced from seawater using electrolysis. "Before the cooling water can be returned to the ocean, it must be treated and monitored. Our analysis stations ensure that the water treatment is carried out in accordance with applicable environmental protection regulations," says Schwäbe. As there are always hazardous areas on board FPSO tankers, the analytical instruments must also be protected accordingly to prevent an ignition source in the event of a malfunction.

The cooling water used on an FPSO must be analysed and treated before it can be returned to the ocean.

Water Quality Determines the Lifetime of Systems

Water analysis also plays a decisive role in the production of green hydrogen. The electrolyzers are fed with demineralized water. The lifetime of the electrolysis stacks, a series of several electrolysis cells that use electricity to split water into hydrogen and oxygen, depends to a large extent on its purity. "Exceeding the limit values can lead to a drastic drop in the performance of the electrolyzer after a very short time. We are talking about a period of minutes or hours. Any contamination leads to a loss of performance and a shortened lifetime of the system," explains Schwäbe. Continuous monitoring and real-time feedback of the water quality is crucial for the efficiency and lifetime of an electrolyzer.

Water quality is similarly critical when ultrapure water is required for the production of pharmaceuticals or semiconductor materials. Even very small amounts of minerals can make a significant difference here. Schwäbe emphasizes: "We offer online analysis systems with which impurities of a few billionths—i.e. ppt, parts per trillion—can be measured accurately." The long list of ingredients that the instruments detect ranges from silicic acid to sodium, oxygen, ozone, and organic compounds "TOC" to the extent of turbidity.

Safe Water Analysis in Hazardous Areas

In chemical and pharmaceutical processes, on FPSO tankers, at LNG terminals, and in electrolyzers for the production of green hydrogen, combustible gases and vapors are naturally involved. The operating locations of the analysis systems are therefore inevitably located in hazardous areas. The electrical apparatus used there must have appropriate protective devices in accordance with explosion protection regulations.

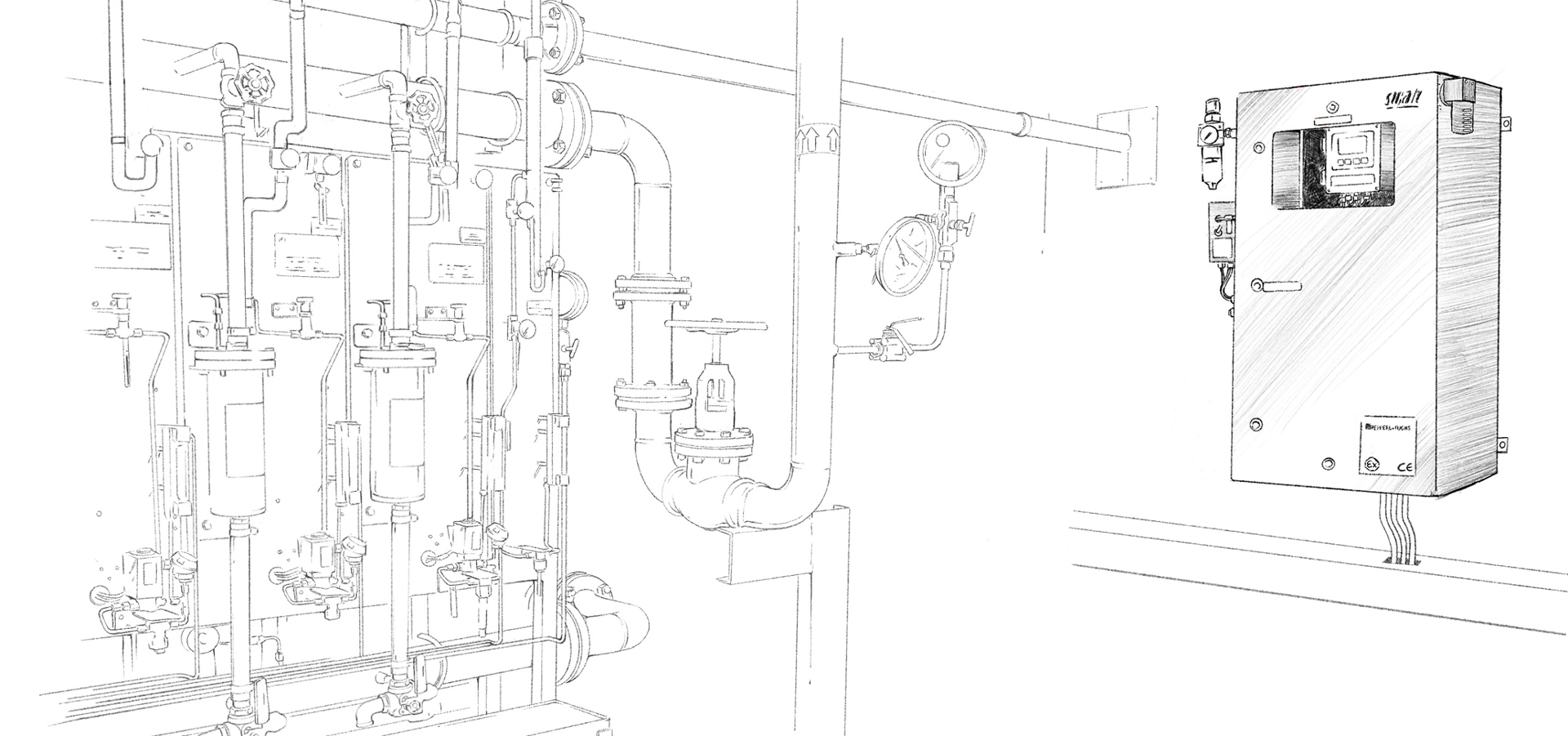

For this purpose, Swan relies on a tailor-made enclosure solution of the type of protection Ex p, or Ex p for short, from Pepperl+Fuchs. This type of protection enables the use of non-certified electrical apparatus for hazardous areas. The manufacturer's online analysis devices are housed in a pressurized enclosure with an integrated operating unit and associated enclosure protection vent, designed precisely to Swan's requirements. Clean air or an inert gas, i.e. a non-flammable gas such as nitrogen, is flushed into this Ex p housing so that the explosive atmosphere is displaced from the housing.

"The pressure control ensures that the internal pressure is constantly a few millibars above the pressure of the potentially explosive external atmosphere. This ensures that the apparatus installed inside can be operated safely and in its intended function without its own Ex approval," explains Alexander Aust, Product Marketing Manager for Electrical Explosion Protection Equipment and Solutions at Pepperl+Fuchs in Mannheim. The enclosure protection vent controls the pressure level in the enclosure and, if necessary, allows inert gas or air to flow in to reliably exclude the ambient atmosphere.

Robust Pressurized Enclosure Solution with a Certain Level of Comfort

Marcel Zuppiger, Sales Engineer at Pepperl+Fuchs in Switzerland, and his team colleagues supported Swan in finding the optimal solution right from the start: "Swan's wide range of analysis systems can be mounted in the pressurized enclosure tailored for use in Zone 2 hazardous areas." The control unit of the Bebco EPS 5500 pressurized enclosure system is attached to the outside of the housing and is both easy and intuitive to operate.

"The display of the Swan transmitter had to be easy to read from the outside through a viewing window integrated into the Ex p housing," Zuppinger reports on one of Swan's key requirements. It was also important for the analytical instrument manufacturer to have a slim and compact housing into which preconfigured Swan instrument panels could be integrated. The engineers at Pepperl+Fuchs designed an Ex p solution for this purpose, which is now part of the Swan portfolio as a standard product and can be used flexibly for various intended purposes. "We wanted an Ex p enclosure for all our products and applications that is easy and intuitive to use and has the necessary ATEX and IECEx certifications for use in hazardous areas worldwide," says Schwäbe, adding: "Pepperl+Fuchs was the only supplier that was prepared to develop a suitable solution for us that absolutely met our requirements, was not 'over-engineered' and offered good value for money."

"The integrability of our measuring and analysis systems in our customers' plants around the world is particularly important to us," emphasizes Schwäbe. "The compact dimensions of the Ex p enclosure and its robustness alone speak in favor of this solution. But above all, we can offer it to our customers as a standard solution with flexible configuration," says Schwäbe, explaining Swan's priorities. In addition to the high quality of the analysis systems, a particularly short delivery time is one of the company's strengths. "As we assemble the Ex p housings to customer specifications in our own workshops, we can usually deliver orders within a few weeks," says Schwäbe

The devices are assembled in Hinwil into multi-stage analysis systems at the customer's request. They can be installed indoors or under a canopy outdoors.

From Customized Solution to Modular Standard Product

The customer-specific Ex enclosure solutions are developed, designed, and manufactured in one of Pepperl+Fuchs' six global Solution Engineering Centers (SECs) in Bühl, Germany. The close cooperation between Swan, Pepperl+Fuchs Switzerland, and the SEC made this tailor-made solution possible. While the first examples were assembled with the analytical instruments at the SEC in Bühl, Swan is now assembling its own stock of Ex p housings. The enclosures prefabricated by Pepperl+Fuchs and already certified to ATEX and IECEx with pressurized enclosure control unit and enclosure protection vent are now installed individually in Hinwil with the equipped instrument panels. Once developed, the customized solution can be ordered as a standard product at any time. "The speed and flexibility that we offer our customers is something we also experience at Pepperl+Fuchs," says Schwäbe happily. "While the competition could hardly be persuaded to submit an offer, we found open doors and ears here. The cooperation was extremely constructive and goal-oriented right from the start. As a result, we are the only manufacturer in our segment to offer a modular standard solution that can be delivered fully assembled, tested, and certified ex works," Schwäbe sums up with satisfaction.

The Water Quality Is What Matters

Water is essential for life. To protect drinking water from contamination, its quality must be constantly monitored. Water from deeper layers of rock can also contain methane, which must be removed before it can be bottled as natural mineral water. However, the quality of the water is not only crucial for drinking water. The same applies to swimming pools, where the water must be regularly checked and treated to remove dirt and bacteria. The Swiss company Swan Analytical Instruments AG, which specializes in the development and manufacture of online instruments for the analytical determination of various parameters in water treatment processes, grew out of these two niches. In recent years, the market for power plants and industrial applications in water analysis has continued to develop and Swan is now one of the leading full-service providers for water monitoring.

Subscribe now

Would you like to find out more about customized solutions from Pepperl+Fuchs? Register via the form below to receive regular updates.

Receive regular updates on customized solutions from Pepperl+Fuchs!

Subscribe now