February 10, 2026

A Partnership in Innovation

A joint AS-Interface development project launched in 2010 marked the beginning of a successful innovation partnership between KNAPP and Pepperl+Fuchs. With the introduction of IO-Link motor control modules, the two companies are driving greater efficiency, flexibility, and sustainability in modern intralogistics systems.

What began in 2010 as a joint development project for customer-specific AS-Interface (ASi) solutions, quickly developed into a lasting partnership that continues to this day. Since then, Austrian technology company KNAPP AG and Pepperl+Fuchs SE have shared a deep technical understanding and a commitment to jointly advancing innovative solutions for intralogistics.

When KNAPP was looking for a powerful IO-Link-based solution for motor roller control in 2019, Pepperl+Fuchs was once again the chosen partner—with the aim of further increasing the availability, transparency, and sustainability of the systems.

Two Companies, One Vision

The two companies have been working closely together on technical projects for over 15 years. After jointly developing the ASi-based solution that led to the G20 series for motor roller control, they went on to develop modules with local logic without PLC connection. In 2019, KNAPP again requested to equip the motor control modules with IO-Link technology: “At that point, KNAPP had already formulated very specific requirements and recorded them in a specification sheet,” recalls Frank Ebert, Head of Development for Industrial Communication at Pepperl+Fuchs.

This was motivated by a desire for technological advancement: “As we were increasingly reaching the limits of AS-Interface due to its restricted bandwidth, we decided to consistently align peripheral control with IO-Link,” adds Claus Blödorn, Development Project Management at KNAPP. As another potential supplier was unable to meet the mechanical and design specifications, Pepperl+Fuchs once again came into focus: “We were initially unaware that Pepperl+Fuchs also implements such specialized developments in the field of IO-Link in addition to AS-Interface,” adds Blödorn.

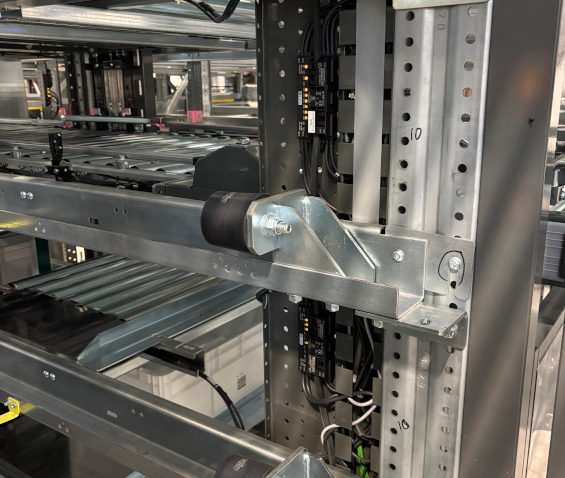

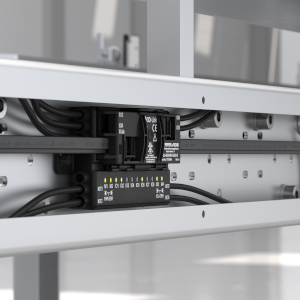

Close technical coordination led to an advanced development of the AS-Interface module, combining the advantages of IO-Link technology in a compact motor control module. Initially developed for KNAPP's own shuttle system, the concept was then extended to IO-Link motor control modules for conveyor technology.

Today, the system is successfully used in online retail and pharmaceutical wholesale—industries characterized by high throughput rates and high inventory turnover.

As an automated small parts warehouse, the shuttle system stores, picks, buffers, supplies, and sequences goods for a wide range of applications. The automated shuttle solution enables higher productivity and increased storage density.

Collaboration as Equals

The close cooperation between the experienced development teams was crucial to the success of the project. Solutions were developed in regular web meetings with technical experts from both sides—more in the style of practical workshops than traditional coordination meetings. “During the intense development phase, useful optimizations, even beyond the original specifications, could be implemented quickly and easily,” explains Blödorn. “This close and trust-based relationship was ultimately the key to success.”

Based on many years of experience with the G20 series motor control modules, the integration of the new IO-Link-based system at KNAPP also went smoothly. “After internal tests and selected pilot projects, it became clear after six to twelve months that the solution is stable and can be approved for all future shuttle systems,” confirms Blödorn.

“IO-Link opens up many new possibilities, which naturally raise questions in the initial phase,” recalls Ebert of the test phase. These included, for example, the cycle times of individual IO-Link masters or initial PROFINET stack problems, which, however, could be quickly resolved.

Increased Efficiency, Fewer Error Sources

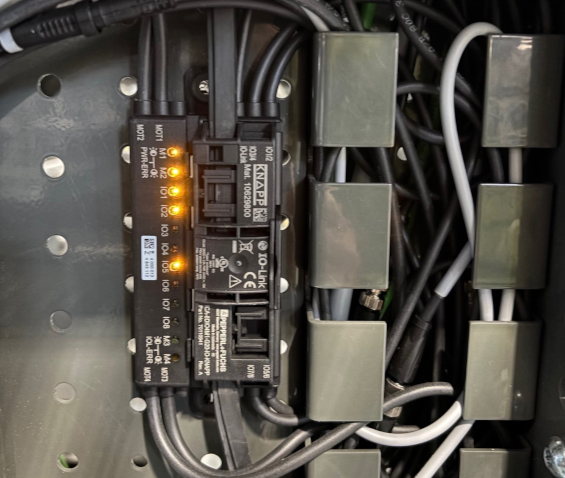

The switch to IO-Link brought noticeable improvements—both in technical and organizational terms. With AS-Interface, the modules had to be pre-addressed and installed in exactly the planned order. "With IO-Link, this is no longer necessary. The modules are installed without preconfiguration and are assigned their function simply by plugging them into the correct master port. This greatly reduces the potential for errors," emphasizes Blödorn.

The new IO-Link modules combine several functions in a single device: Each module has four freely configurable motor outputs. This allows the speed of individual motor rollers to be adjusted flexibly.

The technicians at KNAPP also report significant improvements in commissioning and servicing, says Blödorn: “The advantages of plug-and-play capability also come into play when replacing modules. Each module can be used immediately without any time-consuming handling.”

At the same time, field use always reveals potential for optimization, as Ebert knows: “That’s why we have further developed the product together with KNAPP—with optimized cable lengths and an extended voltage range of up to 48 V.” This now makes it possible to connect more powerful motor rollers, thereby expanding the range of applications.

A Partnership That Accelerates Innovation

Fifteen years of joint development show that KNAPP and Pepperl+Fuchs are connected by much more than technology. Both companies share the same view of future challenges and opportunities in automation. Today, G20 modules with IO-Link already provide valuable information on operating hours and temperature, laying the foundation for predictive maintenance. “With increasingly intelligent IO-Link sensor technology, it is possible to see the status of sensors and actuators, whether there is a risk of overload, or when maintenance is required,” says Blödorn, explaining the predictive maintenance approach. This allows plant personnel to intervene at an early stage and avoid unplanned downtime of the conveyor systems.

Both partners also see further potential in the field of energy efficiency: “The key is to switch off certain plant components during idle times in a targeted manner, thereby achieving sustainability in cost savings,” summarizes Ebert. In addition to energy optimization, KNAPP and Pepperl+Fuchs are pursuing the goal of fully automated configuration—right down to central firmware updates for all components. With IO-Link, the technological prerequisites for this are already in place today.

Tailor-Made for Conveyor Technology

The modules in the G20 series are compatible with all common motorized rollers and offer maximum flexibility for use in conveyor technology. Due to the wide range of variants and protocols, motor control modules with AS-Interface or IO-Link interface and ZPA modules with integrated logic for zero pressure accumulation are available.

Learn more