Following in Amundsen’s Footsteps

September 14, 2021

A tailored solution for marine equipment consisting of an inclination sensor in an explosion-proof enclosure ensures safe lowering of massive anchor chains even in the stormy polar sea.

Equipment under Permanent Stress

Water and oil—two substances that famously don't mix. Yet one country stands out as a perfect example of how these two liquids actually do interact: Norway, with its myriad fjords, lakes, and rivers. Water is a prominent feature here. It provides recreation not only for the Norwegian people but for an ever-increasing number of tourists. It is also the source of Norway's greatest economic gifts: crude oil and natural gas. However, Northern Europe's tough offshore conditions present some very particular challenges for the electrical equipment used to obtain these end products. To function reliably in these conditions, the components must be both suitably rugged and explosion-protected—and the industrial sensors developed and produced by Pepperl+Fuchs are no exception.

'We Norwegians are closely connected to the water and know the dangers and challenges. Reliable technology is essential for survival at sea. Roald Amundsen already knew this when equipping his ships,' says Arve Svela Nikolaisen with a smile, alluding to the legendary Norwegian polar explorer and discoverer of the South Pole. As Key Account Manager at Pepperl+Fuchs, he looks after well-known manufacturers of marine equipment such as anchor and mooring winches: 'There are probably few environments that demand as much of anchor and mooring winches on tankers and oil drilling platforms as the polar seas: seawater, salty corrosive air, permanent vibrations and shocks due to high sea states–daily operation here is a continuous stress test for such components,' he reports. Ensuring reliable operations despite these adversities is the challenge his customers face every day, he says. 'Lowering and retrieving an anchor via one of these winches is a precise interaction between pneumatics, hydraulics and electronics,' he outlines.

Mastering Tough Conditions Together

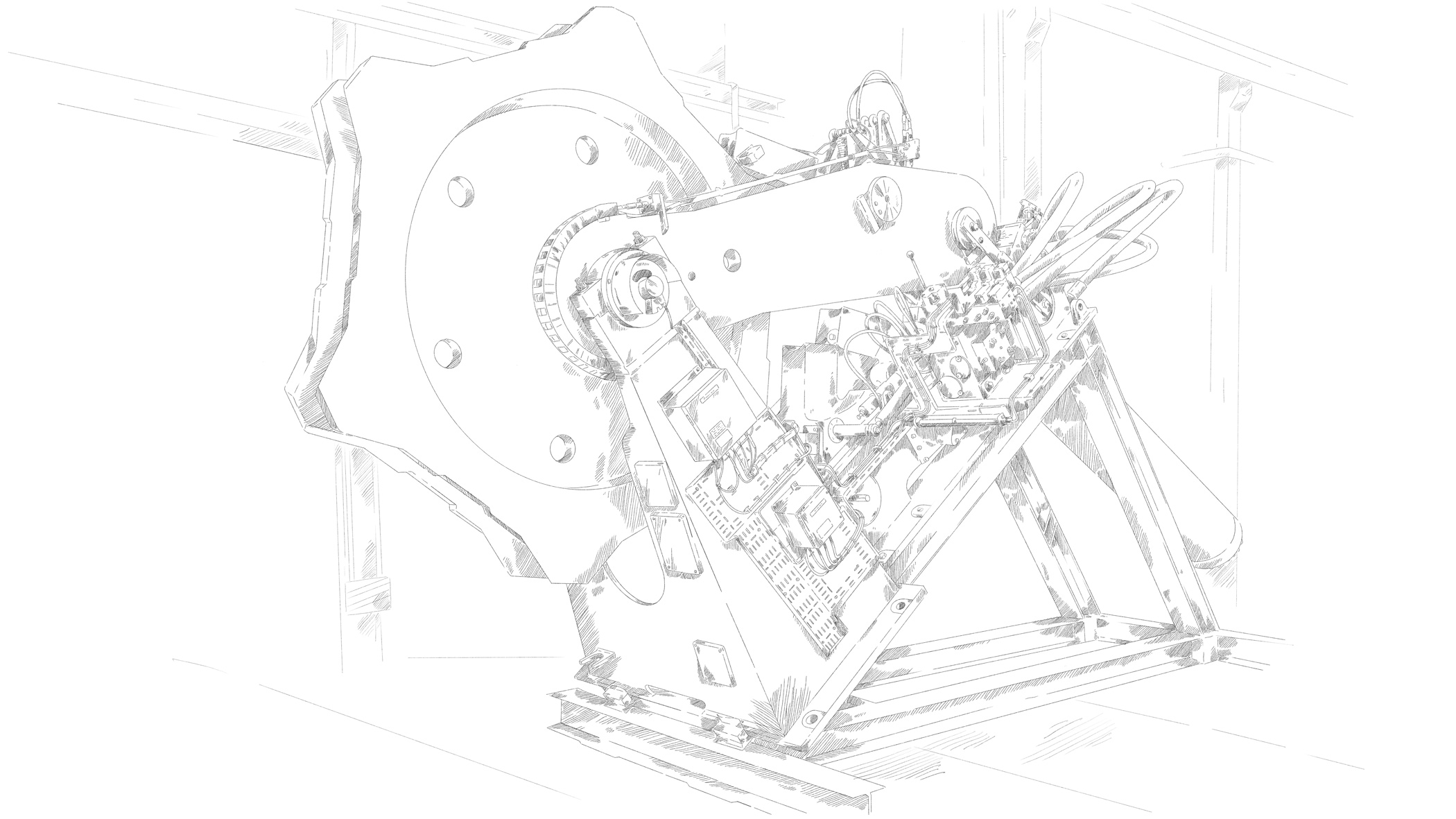

One task that recently occupied a supplier of marine equipment concerned the optimization of the so-called chain stopper–a locking device that serves to relieve the actual winch of the pulling force of the anchor chain when the anchor is lowered. 'A single chain link can weigh up to 280 kilograms. It is important to ensure that the start/stop process is as reliable as possible to prevent material damage and costly operational delays caused by the excessive oscillation of such a large chain. For this purpose, our customer wanted to further improve the accuracy of position determination by using appropriate sensors,' Nikolaisen describes the task that he and his colleagues at the Norwegian Pepperl+Fuchs subsidiary at Porsgrunn were given. 'We have already been working intensively with this customer as a partner in sensor technology for quite some time. On the one hand, they value our exceptionally robust and durable sensors there. On the other hand, we bring the necessary knowledge in the field of electrical explosion protection, which is essential in oil and gas production.'

Porsgrunn in Telemark is the home of the Norwegian Pepperl+Fuchs subsidiary.

Flexibility Is the Key Resource

After an initial analysis of the application, the first idea considered was using explosion-protected, inductive proximity sensors, which are known to be well suited for detecting ferromagnetic metals, such as those used in anchor chain links. 'However, tests revealed that inductive proximity sensors are not an ideal solution for this very particular application. The fierce swell of the sea caused lateral chain motion, resulting in the switching target sometimes being missed,' says Nikolaisen, summarizing the findings from the practical tests.

The team therefore decided to take a different approach, and the sizeable Pepperl+Fuchs product portfolio proved to be a great advantage: The tried-and-tested F99 inclination sensor was the product ultimately selected from the automation specialist's portfolio. This product is often used in the mobile equipment sector on wheel loaders or mobile cranes, for instance. It also seemed to be a suitable solution for this application: With an angular measuring range of 0° ... 360° and good resistance to mechanical shocks and electromagnetic interference, the F99 should be able to deliver precise measurement results for controlling the anchor windlasses and mooring winches using a 4 mA ... 20 mA standard signal.

Not without Explosion Protection

However, another key criterion had to be taken into account for the customer to benefit from these precise measurement results: electrical explosion protection, which is crucial in the oil and gas industry. Since the F99 inclination sensor is not actually certified for use in hazardous areas, some additional measures were required. 'For some time now, Pepperl+Fuchs has increasingly been integrating components without Ex approval, such as RFID read/write heads and distance sensors, into the corresponding explosionproof enclosures. This combination of our expertise is increasingly popular in the factory automation and process automation markets. It opens up completely new possibilities for many users to automate workflows in explosion-protected areas,' says Nikolaisen.

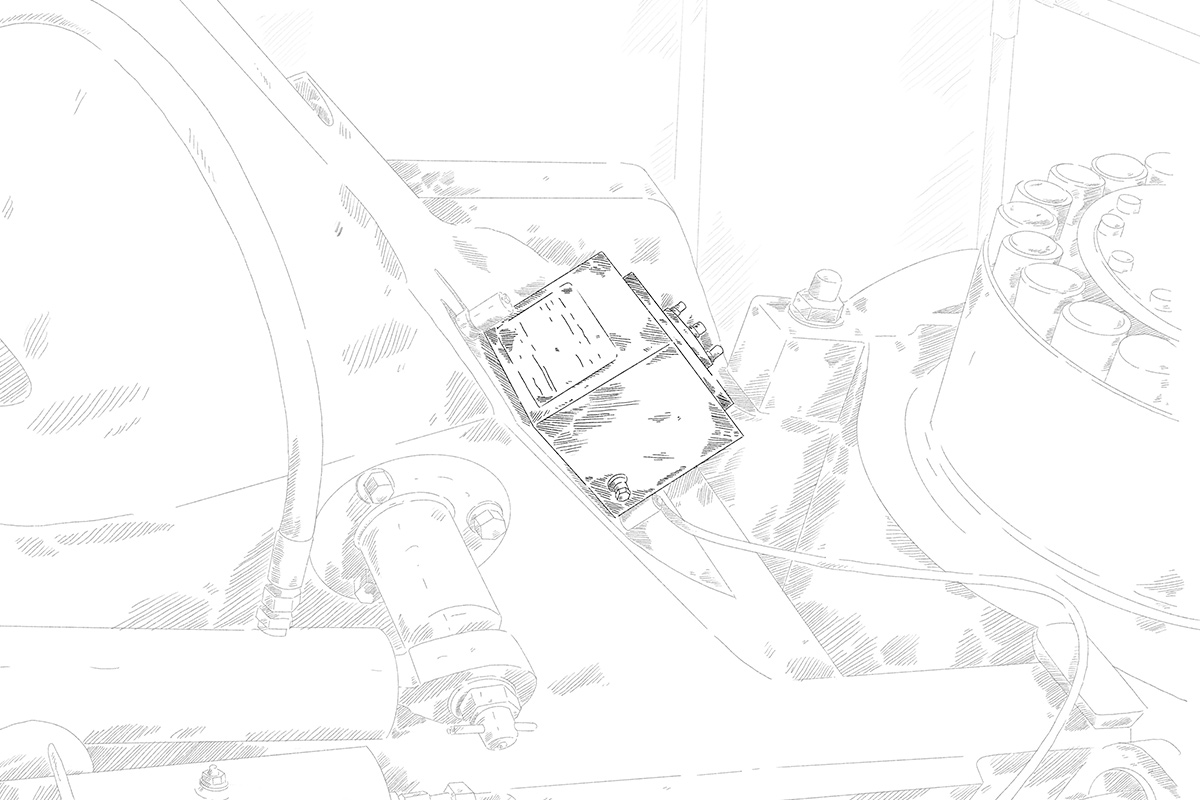

This background led to the F99 being implemented in a flameproof Ex d enclosure. The GUB series from Pepperl+Fuchs was used. This series includes enclosures of varying sizes in both aluminum and stainless steel. 'Given the extreme ambient conditions of the polar seas, we opted for a stainless steel model. With the extremely compact but also rugged enclosure, not only can we fulfill electrical explosion protection requirements but we also benefit from the welcome side effect that the inclination sensor itself receives considerable additional protection from the adverse environment,' says Nikolaisen, explaining the technical implementation.

Down to the Last Detail

Ultimately, Pepperl+Fuchs was able to hand over a turnkey solution that left nothing to be desired. 'For the mechanical protection of the cables, we integrated them into a special cable protection system and developed customized, explosionproof cable glands for this purpose. In addition, we can supply the cables directly in suitable lengths if the installation conditions on an oil rig or ship require adjustments here. This one-stop shopping approach saves the customer valuable time,' says Nikolaisen.

Meanwhile, the results of the cooperation are already in use. Anchor and mooring winches equipped with the new chain stopper solution can now be found not only in the icy polar regions, but also on FPSO ships in the South China Sea. Pepperl+Fuchs is therefore joining the tradition of the great explorer Amundsen alongside a manufacturer of marine equipment―after all, he was not only the first to reach the geographic South Pole, but was also the first person to sail the Northwest Passage from the Atlantic to the Pacific.

Learn more

Our Solutions,

as Individual as You

Subscribe now

Would you like to find out more about customized solutions from Pepperl+Fuchs? Register via the form below to receive regular updates.

Receive regular updates on customized solutions from Pepperl+Fuchs!

Subscribe now