March 13, 2022

Hydrogen: the Key to Energy Turnaround

If you want to curb climate change, you can’t get around green hydrogen—a key factor in decarbonizing transport and industry. The value chain from the wind turbine to hydrogen filling station is long and involves many technical challenges. To ensure the safety of automated processes, explosionproof components and sensors with a wide range of functions are required.

In the 21st century, humanity is working toward a common goal: a significant reduction in CO2 emissions to halt global warming. Decarbonization will create numerous changes, especially in the way we generate, store, distribute and consume energy. ‘The energy transition has so far focused mainly on electricity generation. But now we also need to focus more on areas such as transportation, heating, cooling, and especially heavy industry,’ says Wolfgang Weber, Global Industry Manager at Pepperl+Fuchs.

Hydrogen—A Universal Gas

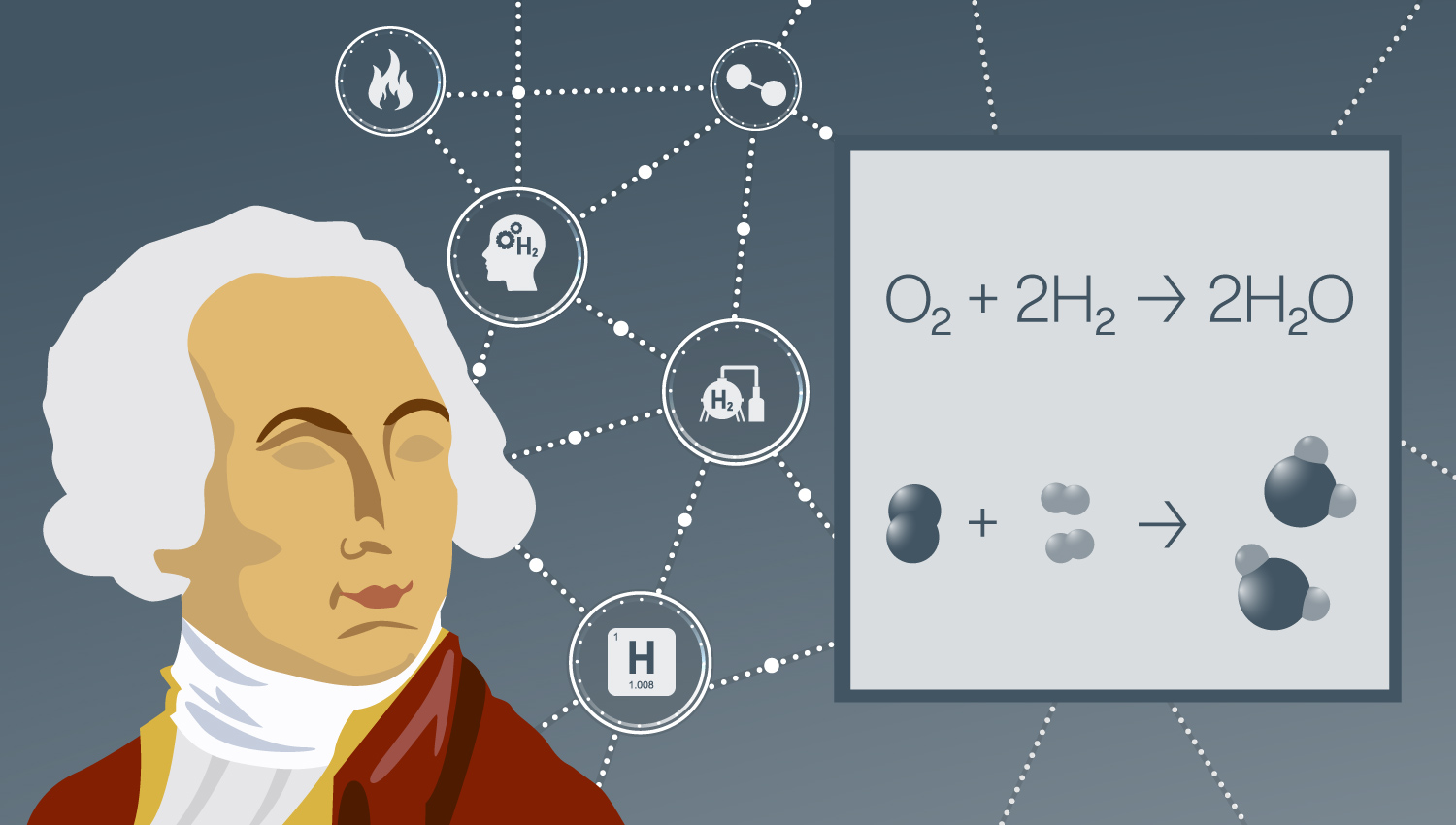

Hydrogen is not only the lightest element, but also by far the most abundant element in the universe. It accounts for about 70 percent of the known mass and 93 percent of all atoms in the universe. In 1783, French chemist Antoine Laurent de Lavoisier discovered that water is formed when hydrogen is burned and named the element ‘hydrogène,’ which means “water former”. Its initial letter ‘H’ later became the symbol for the element in the periodic table of chemistry. When no other substances are present, two hydrogen atoms form an H2 molecule. This is the form in which hydrogen is used in industry.

In 1783, French chemist Antoine Laurent de Lavoisier discovered that water is formed when hydrogen is burned, today known as the oxyhydrogen test.

On Earth, however, most hydrogen is bound up in water (H2O) because it is a highly reactive gas and combines particularly easy with oxygen (O). When the two elements come together chemically, energy is released. If you want to separate them, you likewise have to use energy.

“This explains why hydrogen is the key to carbon-neutral energy,” says Wolfgang Weber. “We can store green energy by using it to split the H2O molecule. The hydrogen can be temporarily stored in tanks and transported through pipelines. When the energy is released again during combustion, only water vapor is produced as exhaust gas. In a fuel cell, the oxidation reaction can even be used directly to generate electricity. Other climate-friendly uses of hydrogen include its use as an alternative to coal to reduce the molten metal needed to produce “green” steel. The universal element can be used everywhere.”

Gray or Green Hydrogen?

But not all hydrogen is “green”— in many industrial processes such as fertilizer production, it is mainly “gray” hydrogen that is currently used. This is produced from natural gas, which releases CO2. The green hydrogen economy, on the other hand, is still in its infancy, but is being heavily promoted. Projects related to green hydrogen are receiving strong government support worldwide, and industry is also largely on board. Large companies from the oil industry and the traditional energy sector in particular have set their sights on hydrogen.

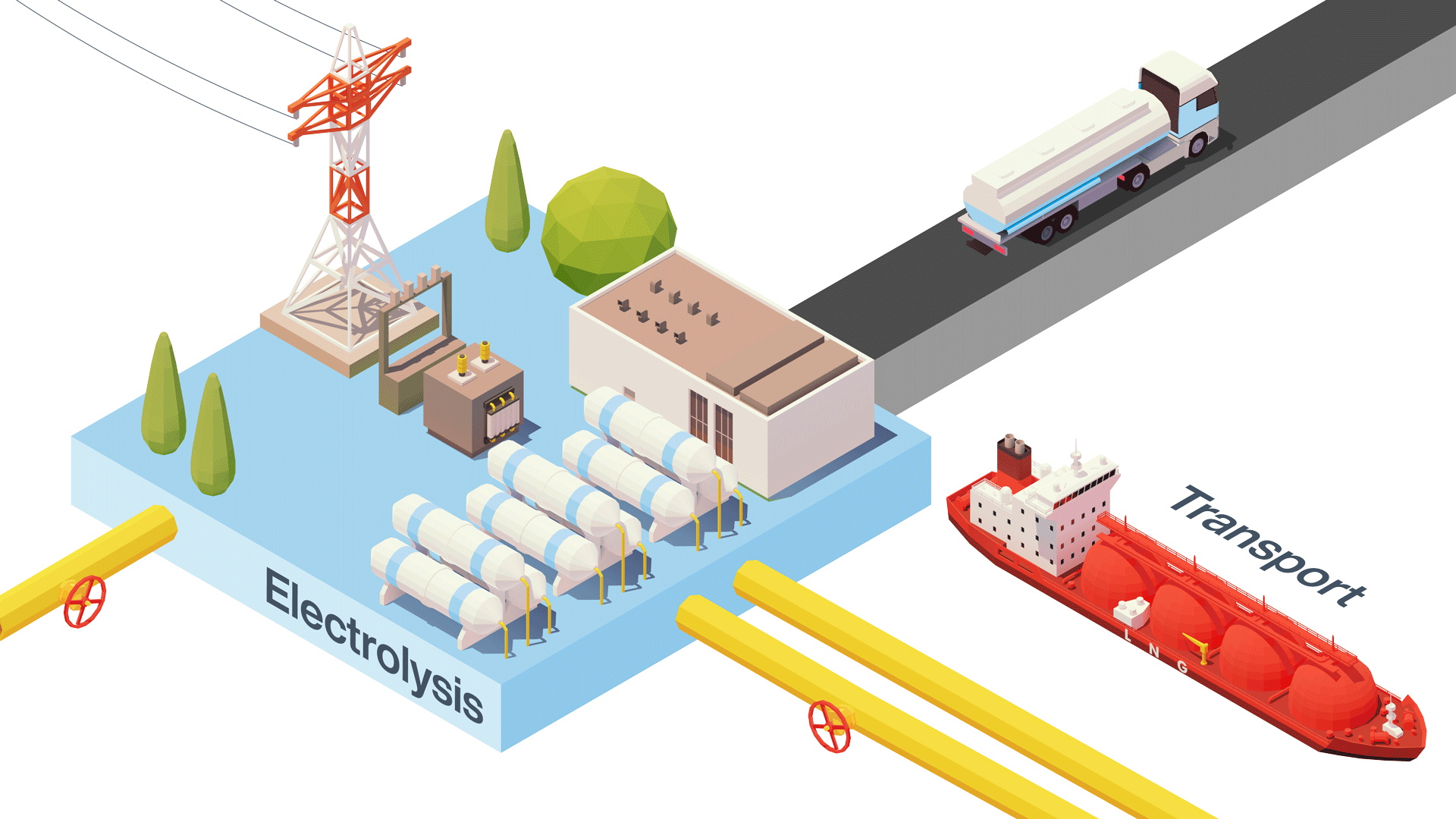

Green hydrogen is produced by the electrolysis of water with green energy. The principle is simple: a voltage is applied in a container filled with water; the hydrogen moves to the negatively charged electrode and the oxygen to the positively charged electrode. It is slightly more complicated in a commercial plant, but numerous people around the world are already working to optimize processes and reduce costs. It is probably only a matter of time before green hydrogen can be produced on a large scale at a competitive price.

Ignitable and Highly Explosive

Hydrogen’s key characteristic—its affinity to oxygen—means that the plant, which includes the electrolyzer and its peripheral equipment, poses an explosion risk. Containers and cables must be sealed as tightly as possible to prevent uncontrolled escape of the gas. In addition, all safety precautions required by laws and standards must be implemented in hazardous areas.

“The same principles that apply to the handling of natural gas can be used. Hydrogen behaves similarly to methane in terms of explosion risk, meaning explosion protection basically works the same for both gases,” emphasizes Thomas Schnepf, Sales Engineer and expert for this application area. “Pepperl+Fuchs has a broad portfolio of connection components for safe signal transmission in potentially explosive atmospheres. These include intrinsically safe barriers, signal conditioners, remote I/O systems, and intrinsically safe mobile devices. Our proven technology works safely and reliably with hydrogen.”

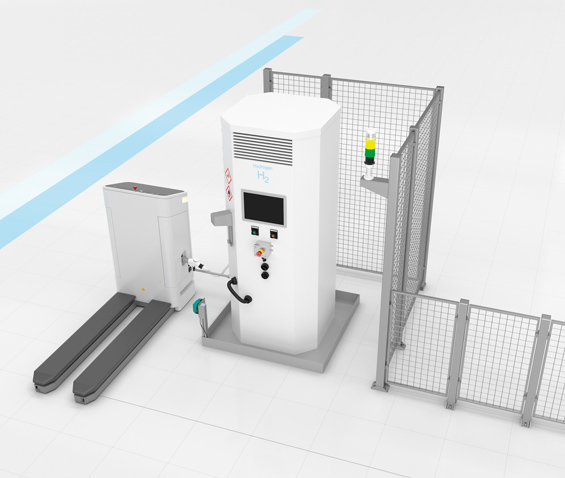

Hydrogen is a very reactive and explosive gas. Therefore, explosion protection is essential for all processes related to electrolysis, such as high-pressure compression, for storage and transport.

Sensors Optimize Wind Yield

Before looking at green hydrogen, one must look at green energy generation. Besides hydropower, the largest green energy sources are the sun and, especially in northern latitudes, wind. According to the Global Wind Energy Council report, by the end of 2020, wind turbines with a total capacity of around 740 gigawatts will have been installed worldwide. This figure corresponds to several hundred thousand wind turbines.

The wind turbines are often located in inaccessible locations and are therefore expected to run for as long as possible without requiring maintenance. But to ensure optimum energy yield, the blades must always be positioned exactly in the wind direction and the angles adjusted. If the wind is too strong, the overload cutoff device must respond in time. Rotary encoders, acceleration sensors, vibration sensors, and inductive sensors record speed, acceleration, and axis position. They therefore form the basis for precise control and condition monitoring of the wind turbines.

Similar positioning tasks are performed by these devices in solar thermal power plants together with inclination sensors. Moving mirrors track the position of the sun to achieve optimum energy yield. “Pepperl+Fuchs offers a wide range of sensors that are needed for the generation of green energy,” explains Wolfgang Weber. “This also applies to the other end of the value chain, such as hydrogen refueling stations.”

From power generation—whether by wind or sun—, high-pressure compression after electrolysis, and transport to hydrogen filling stations, Pepperl+Fuchs offers the right sensor technology and components for explosion protection.

The Limits of E-Mobility

In terms of the number of new installations, hydrogen filling stations are not yet able to keep pace with the increase in electrical charging stations, but their prevalence is gaining momentum. “In heavy-duty vehicles, battery-powered e-mobility is unlikely to be the optimal solution,” explains Wolfgang Weber. “To be able to guarantee the necessary range, batteries like those used in electric cars would simply be too large and too heavy for effective use. In terms of weight and volume, hydrogen offers a much greater energy capacity than diesel or kerosene.”

Well-known truck manufacturers are working on developing hydrogen engines for their large vehicles, and the same is happening in shipbuilding and the aircraft industry. Rail transport is already one step ahead: Germany’s first hydrogen-powered locomotives will be put into service this year, taking over regular services on some railway lines without a power connection.

Hydrogen at the Gas Pump

Refueling with hydrogen is quick—no time-consuming recharging is necessary. But the special properties of hydrogen require a special refueling technique. Among other things, the escape of tiny molecules must be reliably prevented, meaning additional steps are required during refueling.

High-resolution monitors of Pepperl+Fuchs’ VisuNet FLX series can be used to intuitively guide customers through the refueling process. These monitors are suitable for protected outdoor use in hazardous areas and are easy to read even in bright ambient conditions. Inductive sensors monitor whether the fuel dispenser—e.g., the connected H2 filling nozzle—is firmly and tightly connected to the vehicle’s tank; acceleration sensors detect vibrations in the event of a collision and trigger an emergency shutdown if necessary. An RFID system can then be used for fuel management with automatic billing, for example. In combination, these devices ensure safe and convenient refueling and are all available from Pepperl+Fuchs.

Large Hydrogen Quantities for Industry

For CO2-neutral industrial production, hydrogen is needed for processes that require high burner efficiency or the use of a reducing agent. With global CO2 emissions of around 2.8 billion metric tons, the cement industry alone is responsible for about eight percent of man-made greenhouse gases. This figure could be drastically reduced if the kilns were fired with green hydrogen instead of fossil fuels.

The same applies to steam crackers in the petrochemical industry or furnaces in the metal industry and in the manufacture of glass and porcelain. Hydrogen can also replace carbon in the direct reduction process in the steel industry, as it removes oxygen from the iron ore. This means that only H2O and no CO2 is produced in this crucial step.

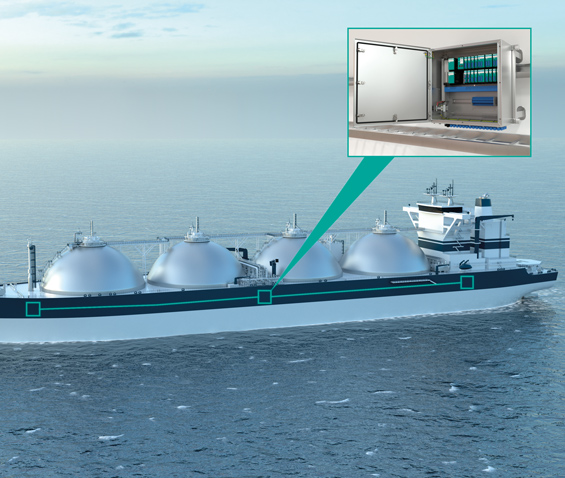

Very large quantities of hydrogen are needed for such processes, which is why industrial companies are supplied with the gas via tankers or directly via pipelines. “Existing natural gas pipelines can be used for this purpose,” explains Wolfgang Weber. “Natural gas already contains a certain amount of hydrogen, and more can be added, bringing the proportion up to 60 percent. The gases are then separated again before use. In the future, only hydrogen could flow through these pipelines instead of natural gas. However, some precautions are needed to protect the pipes, because hydrogen makes conventional pipe steel brittle and also readily reacts with the carbon in the metal. In principle, however, there is already a very well-developed infrastructure that will make the transition to a carbon-neutral hydrogen economy much easier. Important steps in this direction are currently being taken in many areas.”

The coming years will show whether green hydrogen really is the key to the energy transition. What is certain, however, is that green hydrogen will play a fundamental role in energy generation and the decarbonization of industry and heavy-duty vehicles in the future. Pepperl+Fuchs, with its many years of experience in explosion protection and industrial sensor technology, is the right partner and a connecting element in the hydrogen chain—from renewable energy generation to high-pressure compression after electrolysis, transport and storage, to large-scale industrial use and hydrogen filling stations.