June 4, 2024

Fully Electric and Completely Networked

The path to the “All-Electric Society” leads through automation and digitalization in all areas. As an expert in industrial sensors, components, and mobile solutions for hazardous areas, Pepperl+Fuchs offers specific products and technologies for the safety, efficiency, and digitalization of industrial processes through to sustainable IoT solutions for cities.

The future is electric: this was the motto under which ZVEI e.V. (German Electrical and Electronic Manufacturers’ Association) presented the concept of the All-Electric Society at Hannover Messe 2024. Companies from the electrical engineering and automation industry used practical examples to showcase innovative solutions for sustainable electrification, automation, and digitalization in all areas: from industrial production to the energy sector, urban and building management and mobility solutions. Dr. Gunther Kegel, CEO of the Pepperl+Fuchs Group and President of the ZVEI, is certain: ‘The All-Electric Society will lead us to climate neutrality. Without the highest possible level of electrification from renewable energies and the energy efficiency gains resulting from the digitalization and automation of processes, the goal of climate neutrality will turn from vision to utopia.’ In addition to generating energy from renewable sources, the decisive levers lie in increasing energy efficiency and sector coupling. They are the key to the All-Electric Society. ‘We need to save much more energy through efficient solutions and technologies than we will be able to generate from renewable energies in order to meet the growing demand for energy. This can only be achieved through comprehensive electrification, automation, and digitalization,’ says Kegel.

Efficiency Lever: Digitalization and Sector Coupling

However, the energy generated from solar, wind, and hydropower is not available to the same extent at all times. At some times of the day or year, there can be significant energy surpluses or lulls. However, energy cannot always be consumed only when it is available in sufficient quantities and at low cost. This is where storage technologies and intelligent sector coupling play a decisive role. In order to provide energy reliably in sufficient quantities and at competitive prices, the electricity generated from renewable energies must be stored temporarily or converted into green hydrogen or other power-to-X technologies in electrolyzers, for example. ‘If we understand sector coupling correctly, so that the energy-generating and consuming sectors are optimally coordinated, then this is only possible in a fully automated and digitalized way. To achieve this, the machine or system must be able to communicate with the energy producer,’ explains Kegel. Intelligent sector coupling is necessary to achieve a sustainable transformation and efficiency gains in the energy, industry, and transport sectors.

Smart Sensor Technology for Optimum Energy Yield

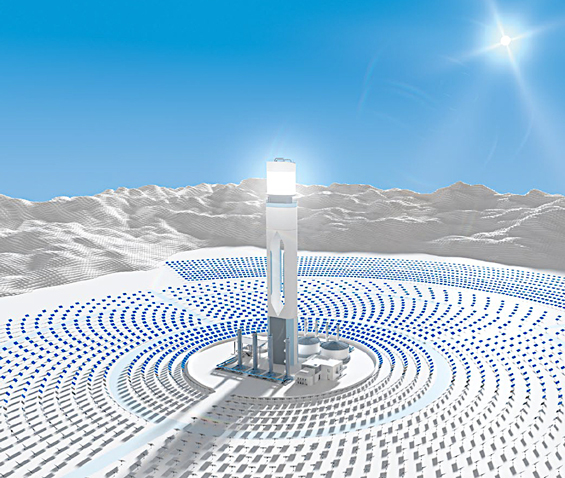

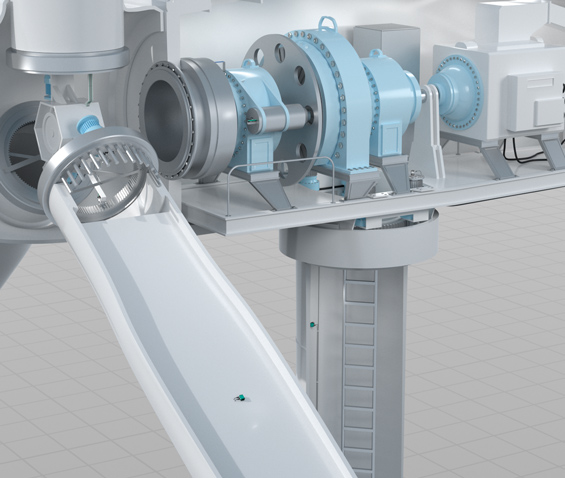

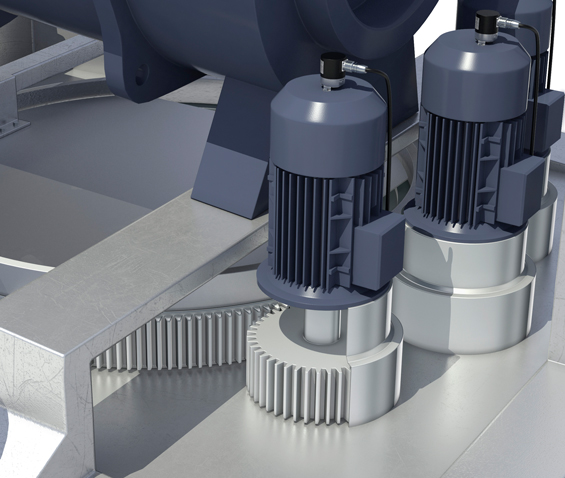

The concept of the All-Electric Society includes the generation of electricity from renewable energies. At the same time, energy efficiency must be significantly increased to compensate for the increase in energy consumption due to comprehensive electrification. ‘The All-Electric Society will not be a reality for at least 20 years, but we need to lay the foundations for it today. This is the only way we can achieve the goal of climate neutrality by 2045,’ explains Kegel. Above all, renewable energies such as wind power, photovoltaics, and solar thermal energy must be massively expanded. Sensors and automation components play a crucial role in the efficient operation of such systems.

Sensor technology from Pepperl+Fuchs has been used in the renewable energy sector for many years to automate wind power, photovoltaic systems, and solar thermal power plants. Rotary encoders, vibration sensors, as well as inclination and acceleration sensors, for example, ensure the optimal alignment of the systems and maximize the yield of energy generated. In order to align photovoltaic modules or heliostats as precisely as possible to the position of the sun, rotary encoders and inclination sensors from the F99 series from Pepperl+Fuchs are used. The same applies to the efficient use of wind energy: to make maximum use of it, the rotor blades of wind turbines must rotate according to the wind direction and be aligned at an ideal angle of inclination. To achieve this, the control system must detect the position of the nacelle and the rotor blades. Absolute rotary encoders from the ENA58 series not only provide the precise position values, but are also perfectly suited for pitch and azimuth control in order to align the nacelle and rotor blades optimally to the wind. ‘In addition to the efficient operation of the turbines, our sensor technology also enables predictive maintenance and servicing, for example by detecting long-term changes in the vibrations and accelerations of turbine components,’ explains Kai Lindner, Key Account Manager Factory Automation at Pepperl+Fuchs.

Versatile Gas: Green Hydrogen for Energy, Transport, and Industry

Alongside solar and wind power, green hydrogen is set to become another important pillar in the energy mix as a sustainable energy source. However, its use is only climate-neutral if the gas is produced using renewable energies. In the transport sector in particular, green hydrogen can close the gap in the mobility transition. Electrification in the passenger car sector is progressing worldwide. In commercial vehicles and heavy goods vehicles, hydrogen-powered vehicles can be an alternative to battery-powered electric vehicles due to their short refueling times, greater range, and payload. In addition, the combustion of hydrogen does not produce any climate-damaging emissions, only pure water vapor. However, refueling with hydrogen poses a number of technical challenges. Due to the explosive properties of hydrogen, the processes at a hydrogen filling station require electrical explosion protection precautions for safe control and signal processing. This is where the explosion protection components and mobile solutions for industrial communication in hazardous areas from Pepperl+Fuchs play a decisive role. This begins with the delivery of the alternative fuel. The robust Tab-Ex Pro industrial tablet from the Pepperl+Fuchs brand ecom is ideal for safely and reliably monitoring the refueling process from the truck to the low-pressure storage tank. A command and signaling device from the LRP series with ‘intrinsically safe’ (Ex i) type of protection ensures a safe signal supply at the low-pressure storage tank. The hydrogen in the filling station system is also subject to several transfer processes: from the low-pressure storage tank to the high-pressure storage tank to the vehicle tank. This requires the gas to be compressed. For the compression of hydrogen, Pepperl+Fuchs offers numerous components for explosion protection, intrinsic safety barriers, pressurized enclosure systems, as well as Ex i and Ex d solutions. They all contribute to the safe and efficient operation of hydrogen filling stations.

However, green hydrogen will not only replace fossil fuels in the transport sector in the future, but also in industrial applications wherever possible. Whether as an intermediate storage medium, a sustainable energy source, or as a material substitute in certain chemical processes— green hydrogen will play a decisive role in the transformation of the energy, industrial and transportation sectors. As a pioneer and innovator in electrical explosion protection, Pepperl+Fuchs knows only too well about the explosive properties of gases. This means that explosion protection guidelines must also be observed along the entire hydrogen value chain. From the production, storage, transportation, and refueling to the industrial use of hydrogen, Pepperl+Fuchs offers the right automation and explosion protection components for the safe and efficient operation of the systems.

Explosion Protection and Digital Solutions for the Transformation in the Energy Sector

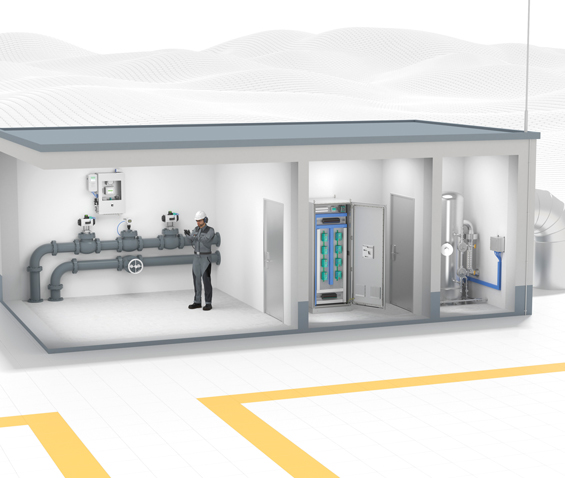

Large quantities of green hydrogen will have to be imported to meet the growing demand for energy. The gas would have to be liquefied at -253 °C for transportation by tanker. However, this is very time-consuming, cost-intensive, and involves high energy losses. For this reason, hydrogen is primarily transported temporarily stored in carriers. Ammonia as a so-called derivative enables easier storage and transportation by ship due to its much higher energy density compared to liquid hydrogen. Ammonia can then be split back into hydrogen and nitrogen by cracking. The advantage: millions of tons of ammonia are already transported by ship every year and safe handling has been established worldwide for decades. The LNG terminals, tank farms, and pipelines available for importing liquid gas could also be used to transport ammonia or hydrogen in the future. As ammonia is also an explosive substance, appropriate precautions for explosion protection are required, as with pure hydrogen.

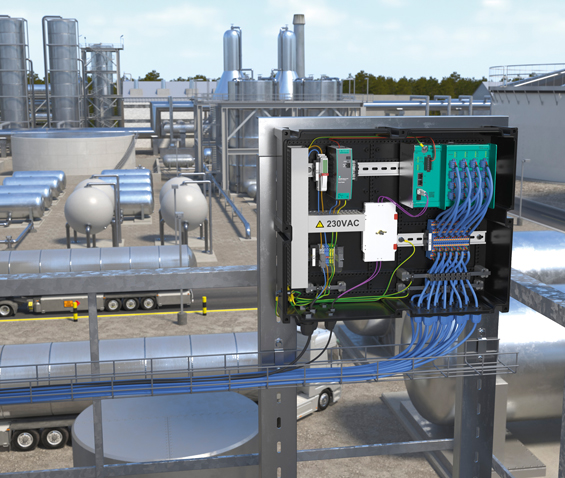

As an expert in electrical explosion protection, Pepperl+Fuchs can provide support in the planning or conversion of LNG terminals to ammonia terminals with know-how and the appropriate products. For example, the intrinsic safety barriers of the K-System from Pepperl+Fuchs ensure safe signal transmission during the safe unloading of the tanker. Tank farms could be equipped with Ethernet-APL in the future to leverage further potential in sector coupling. The two-wire Ethernet for the process industry enables digital data transmission from the field level to the process control level. Data can also be forwarded quickly and securely to higher-level control and management systems via the Ethernet-APL rail field switch. “Overall, Ethernet-APL offers a powerful, digital solution for the integration of Ethernet networks in process plants that increases efficiency while ensuring the safety and performance of your systems,” explains Thomas Schnepf, Sales Engineer for Process Automation at Pepperl+Fuchs. This also enables efficient networking of energy providers, suppliers, and consumers in the energy sector. “Ethernet-APL contributes to realizing the vision of an All-Electric Society by creating the basis for digital data transmission and the resulting more efficient energy supply in industrial applications,” Schnepf summarizes the advantages of the technology.

Digitalization and Virtualization Reach the Process Industry

‘With Ethernet-APL, a physical layer specially tailored to the process industry is now available for IP communication in hazardous areas. For the first time, it is possible to digitize the store floor without additional costs: the analog interface is simply replaced by an Ethernet-APL interface,’ says Kegel. The latest scalability tests show that the technology is ready for use. After intensive and successful load tests under realistic conditions with approx. 240 Ethernet-APL field devices, ten Ethernet-APL field switches, and three redundant process control systems, one of the heavyweights of the chemical industry was convinced: the implementation of an intrinsically safe two-wire Ethernet for the process industry is feasible. The chemical company BASF is now equipping a new production plant at its German headquarters in Ludwigshafen am Rhein with Ethernet-APL rail field switches from Pepperl+Fuchs. The first greenfield projects with Ethernet-APL are also already being set up in Asia.

However, it is also worthwhile for operators of existing process plants to take a closer look at the topic. Ethernet-APL supports the trunk-and-track topology firmly established in the process industry and can be used with any Industrial Ethernet protocols such as EtherNet/IP, HART-IP, OPC UA, and PROFINET. The existing instrumentation with PROFIBUS PA can be retained, as the Ethernet-APL rail field switch adapts to the communication and protocol and automatically translates the device data into PROFINET. There is no need to replace the field devices or reinstall the connection technology. In short: migration to the modern two-wire Ethernet is possible for all process systems and is also easy to implement. Communication and digital data transmission of up to 10 Mbit per second from the control system to the field device takes place without any additional gateways or protocol conversions. “Ethernet-APL ensures that systems work more efficiently, that large volumes of data can be transferred quickly, and that field devices can be used efficiently for process and diagnostic information,” explains Schnepf. Converting the system to fully digital communication with Ethernet-APL enables end-to-end process optimization from production to system maintenance.

In the course of digitalization, the virtualization of systems and applications is also increasing in the process industry. With its diverse VisuNet portfolio of human machine interfaces (HMIs), Pepperl+Fuchs offers a large selection of robust industrial monitors, operator stations, and slim remote monitors as well as industrial thin clients for worldwide use in chemical and pharmaceutical production and the oil and gas industry. The thin clients from Pepperl+Fuchs are specially designed to meet the requirements of harsh environments and enable IoT applications and the virtualization of process control systems. Together with Ethernet-APL, they take process plants to a new level of digitalization and make them ready for Industry 4.0 applications.

Digital Workflows with Intrinsically Safe Smartphones and Robust Industrial Tablets

Mobile devices are undoubtedly part of digital communication in real time. Smartphones and tablets have long since become an integral part of everyday life, both at home and at work. However, their use in regulated areas is not possible without further ado. To simplify communication and collaboration between the control center and mobile workers in the field of process plants, Pepperl+Fuchs offers intrinsically safe mobile devices such as smartphones from the Smart-Ex® series and tablets from the Tab-Ex® and Tab-IND series for safe and digital communication in harsh industrial environments and hazardous areas. The secure, robust, and powerful devices enable digitalized and therefore efficient and transparent workflows. ‘With digital workflows, software applications and augmented reality applications, processes can be optimized, resources saved and costs reduced in the long term,’ says Schnepf. Due to the intrinsically safe smartphones and tablets from Pepperl+Fuchs, plant operators and mobile workers can access information anywhere and at any time and transfer data in real time to the controller, the process control system, or directly to a cloud.

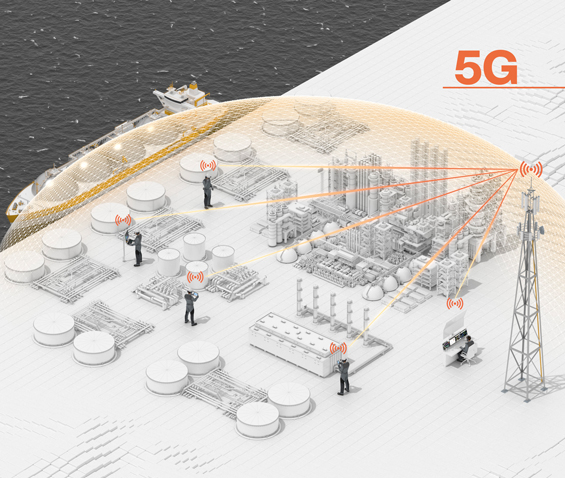

The 5G smartphone Smart-Ex® 03 with Wi-Fi® 6 takes digitalization in hazardous areas to the next level. Whether for efficient troubleshooting in the plant, the digital dispatch of work orders and spare parts orders, or remote support for maintenance and servicing of devices or plant areas—the powerful 5G technology enables the transmission of large amounts of data and precise localization in the field. 5G can also be used to set up company-owned, self-sufficient networks that also prevent sensitive data from being leaked to the outside world.

City, Country, River: Smart, Outdoor-Ready IoT Sensors

In addition to industrial sectors, digitalization is also increasingly finding its way into cities and municipalities. It is not only the world’s metropolitan areas with millions of inhabitants, but also increasingly smaller cities and municipalities that are developing into smart cities. More than half of the world’s population already lives in cities. According to forecasts, this figure will rise to more than 65% of the world’s population by 2050. It is therefore obvious that there is an enormous need for action here in order to achieve the global goal of climate neutrality. Here, too, the focus is on climate change, sustainability, and energy efficiency.

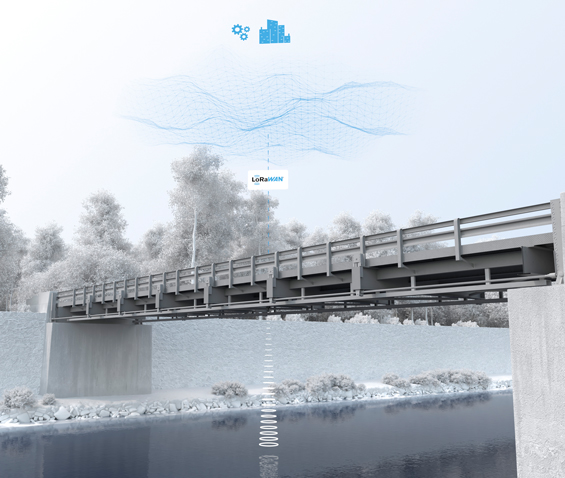

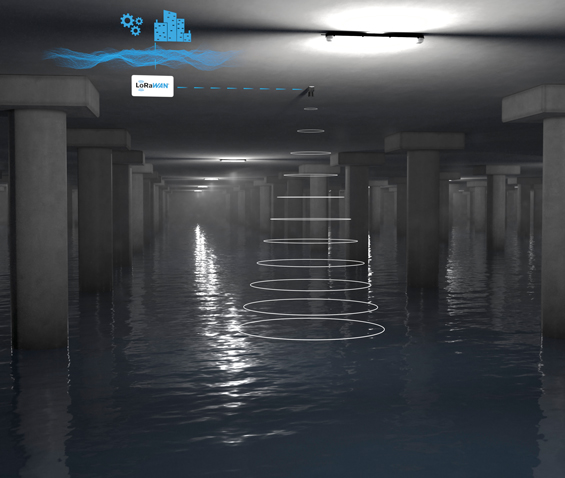

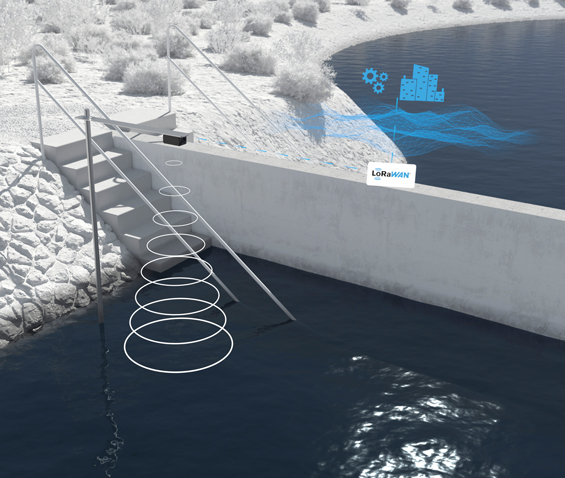

Particularly in times of climate change, intelligent and efficient solutions are required, such as for optimized and needs-based waste disposal, reliable flood warning systems on rivers, or reliable level monitoring in rainwater retention basins. Pepperl+Fuchs has developed the WILSEN.sonic IoT sensor for precisely these applications and requirements for a sustainable and resource-conserving society, urban development, and industry. The portfolio of robust, battery-operated IoT ultrasonic sensors is equipped with a powerful lithium battery that enables many years of maintenance-free operation. The WILSEN.sonic sensor transmits its measurement data via the globally standardized, radio-based LoRaWAN® technology. This enables energy-efficient signal transmission over distances of several kilometers using adjustable transmission intervals. The devices deliver reliable measurement data even under harsh environmental conditions. The radio-based IoT sensors have already proven themselves in several projects as an ideal solution for smart city, smart waste, smart environment, and industrial applications in the context of sustainability.

‘Enabler’ of the All-Electric Society

‘The entire electrical and digital industry sees itself as an ‘enabler’ of the All-Electric Society, for the transformation to a climate-neutral and sustainable society and industry,’ explains Kegel. With its many years of experience in the automation and digitalization of industrial processes, Pepperl+Fuchs already offers solutions for efficient and sustainable production processes. Industrial sensors for optimum yield in the generation of renewable energies, explosion protection components along the hydrogen value chain as well as industrial-grade, mobile communication solutions contribute to efficient and sustainable electrification. Future technologies such as Ethernet-APL or outdoor-compatible IoT sensors with LoRaWAN wireless technology ensure efficiency increases and process optimization with digital data transmission and a sophisticated energy supply. The path to the All-Electric Society is paved.