November 5, 2017

Melting Pot on the Indian Ocean

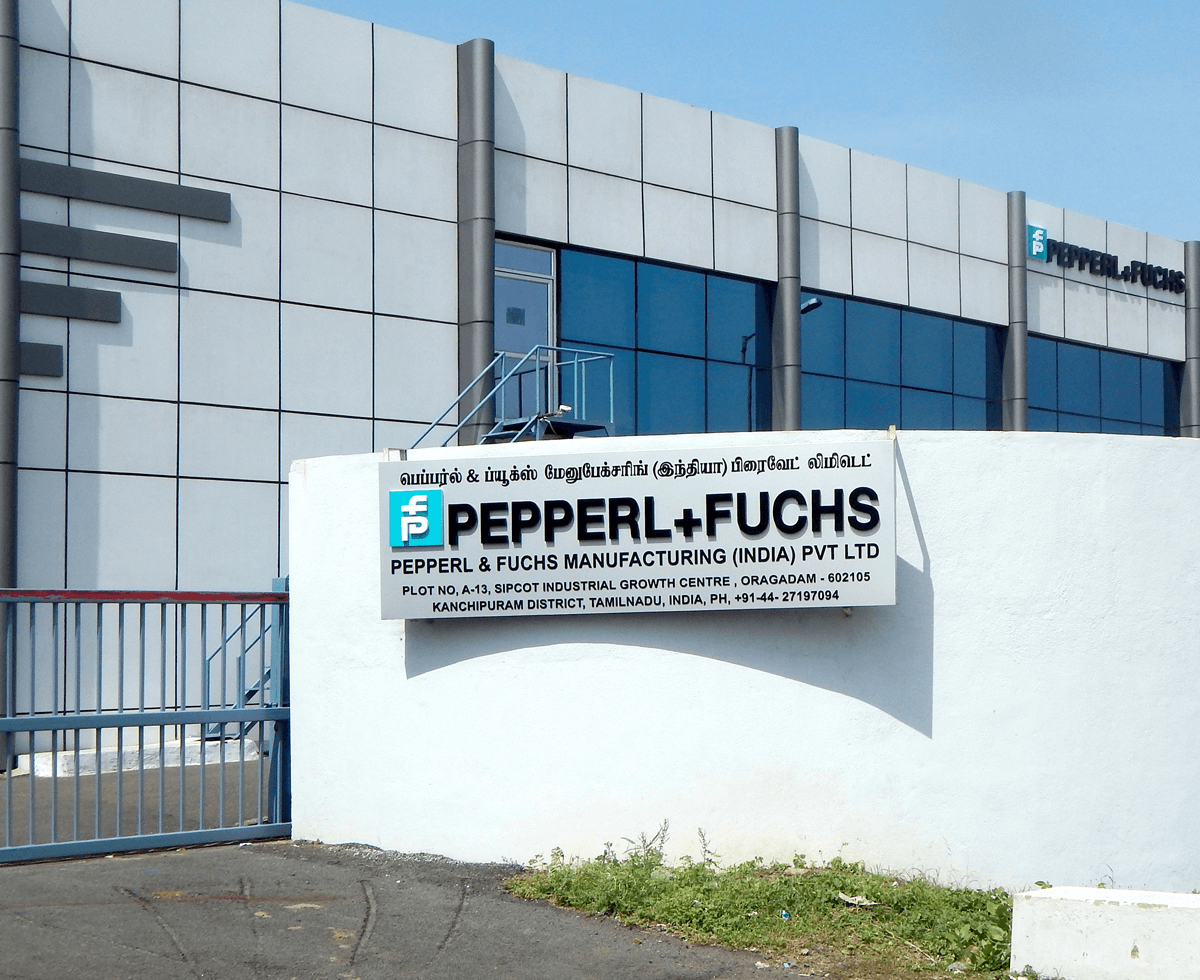

Whether it’s the landscape, people, religions, colors, or spices—India is a country of unparalleled diversity. Since 2016, Pepperl+Fuchs Manufacturing (India) Private Limited in Chennai has been diversifying the Pepperl+Fuchs family and supplementing the value chain in the electrical explosion protection business with its own foundry.

Exotic curry, the impressive Taj Mahal, colorful Bollywood: Anyone who has not yet visited India only has a vague idea of the second largest country in Asia. And yet, India has long been one of the most important business locations in the world. With a growth rate of 7.6%, the country was among the fastest expanding economies in the world in the 2015/2016 fiscal year. Although the majority of the population is still employed in the agricultural sector, a number of large industrial centers have developed in the land of colors and spices within the last few decades—such as Chennai, formerly Madras. Situated on the Indian Ocean, the city is dominated by the automotive sector, yet other important sectors such as the chemical and petrochemical industry have established themselves there, too. “Chennai is very industrial. A large number of metal processing plants and foundries that supply large local businesses have been set up in the city,” is how Hermann Best, Vice President of Global Sales Processes at Pepperl+Fuchs, describes the local environment. In 2016, after the acquisition of former Petroleum Safety Products Industries (PSP) in Chennai, Pepperl+Fuchs thoroughly integrated one of these plants into its own Group, and is now also implementing its stringent quality standards in the production of enclosures.

A Production Plant with Its Own Foundry Offers Perfect Conditions

The team at the new production facility in Chennai consists of approximately 100 employees who work mainly in manufacturing but also in production planning, engineering, and development. They currently design and manufacture enclosures and complete engineered solutions for India, Australia, and the Middle East.

“This year, we want to modernize the facility as part of an ambitious investment project and expand it to a global scale which will allow the plant to supply further Solution Engineering Centers in our worldwide network with Ex d enclosures for end-to-end engineered solutions,” Best forecasts. “This will allow us to provide standards and quality for our customers in all parts of the supply chain.” This means that, in the future, Pepperl+Fuchs Manufacturing (India) Private Limited will be an important cornerstone for core components of the Pepperl+Fuchs electrical explosion protection portfolio.

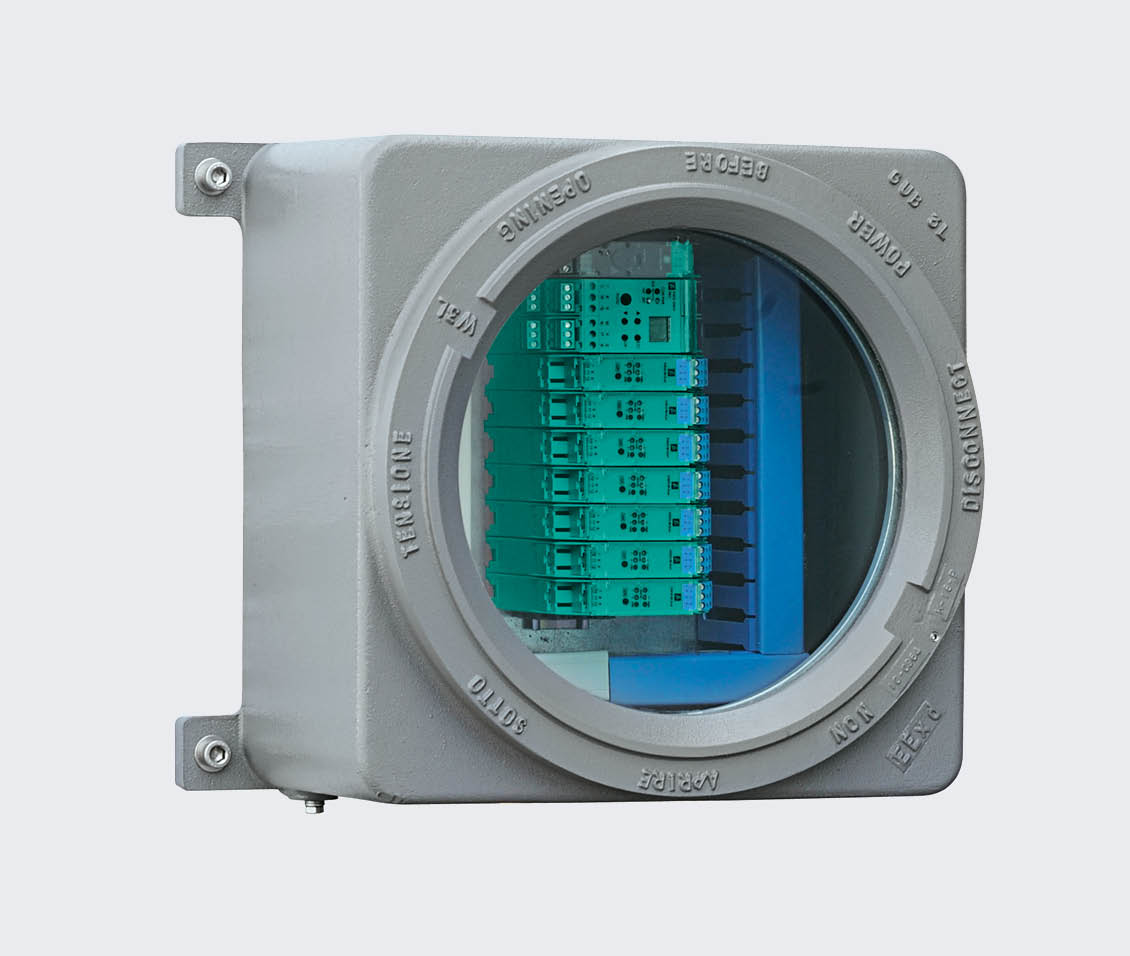

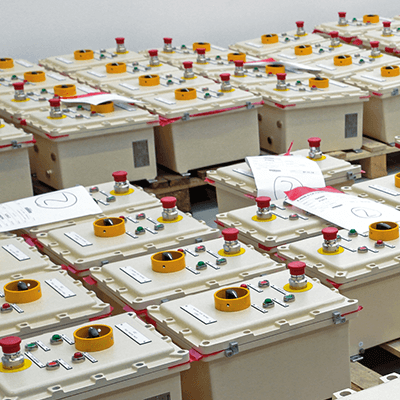

“The thoroughly modernized foundry and manufacturing facility will then mainly produce empty enclosures of protection type ‘flameproof enclosure’ (Ex d) in accordance with the latest standards, for processing on milling and turning machines immediately after casting,” is how Best describes the planned on-site manufacturing processes. “The enclosures will then be tested and put through pressure testing before a powder coating is finally applied to the surface.” At Solution Engineering Centers, the enclosures are then used as the basis for manufacturing explosion protection solutions that are designed on a customer-specific basis. All work and processes are subject to the high internal standards that apply to all facilities within the Group. “This means that our customers can rely on the quality and safety they are accustomed to in our electrical explosion protection solutions,” sums up Best.

More for the Customer

With its new facility, Pepperl+Fuchs is transferring not only its quality standards but also its in-depth explosion protection knowledge relating to the production and processing of Ex d empty enclosures. “The acquisition allows us to increase our vertical integration and develop additional capacity for the electrical explosion protection equipment business segment. This means that, in the future, we will be able to handle the needs and requirements of our customers with greater speed and with a more systematic approach.” A manufacturing facility with its own foundry was the missing piece of the puzzle for Pepperl+Fuchs in terms of production: “Now the entire value chain for complete solutions in electrical explosion protection is in our hands. We provide customers everything from a single source, from the foundry to the finished solution,” says Best.